Top Power Heavy Equipment Machines for Your Construction Needs?

In the world of construction, selecting the right machines is crucial. Power heavy equipment plays a pivotal role in ensuring efficiency and productivity on job sites. From bulldozers to excavators, each piece of machinery serves specific functions. The right tools can streamline operations and reduce labor costs significantly.

However, not all power heavy equipment is created equal. Factors like equipment durability, ease of use, and maintenance costs matter greatly. It's important to reflect on your project's unique needs. Relying solely on brand reputation may not always lead to the best choice.

Often, businesses may overlook the importance of equipment knowledge. Understanding the capabilities of each machine can lead to better decision-making. Poor choices might result in delays and added expenses. Investing time in research can pay off tremendously in the long run.

Overview of Heavy Equipment in Construction Industry

Heavy equipment is essential in the construction industry. These powerful machines enhance productivity and efficiency on job sites. Excavators, bulldozers, and cranes are commonly used. Each machine serves a unique purpose, helping to shape and build infrastructure.

When choosing heavy equipment, consider the project size and site conditions. Not all machines fit every type of job. If the site is tight, smaller equipment may work better. Oversized machines can cause damage and delays.

Tips: Always check the condition of the equipment before use. Look for leaks or wear and tear. Ignoring these details can lead to unsafe conditions. Furthermore, ensure operators are trained. Improper handling can create hazards on site. Remember to review maintenance logs regularly. It’s easy to overlook this, but it's crucial for safety and effectiveness.

Types of Power Heavy Equipment Machines and Their Functions

When choosing power heavy equipment for construction, understanding the types of machines is crucial. Excavators are essential for digging and demolition. They have long arms and varying bucket sizes, which enhance versatility. A bulldozer is powerful for pushing large quantities of materials. It is effective for rough terrain and moving debris.

Forklifts are used for lifting and moving materials at heights. They come in various styles, each suited for different types of loads. Cranes, on the other hand, are designed for heavy lifting over considerable distances. They can be mobile or fixed, providing options based on the site’s requirements.

**Tip:** Always assess your site conditions. This ensures you choose equipment that can operate efficiently. The wrong machine can delay projects and inflate costs.

Another consideration is the maintenance of these machines. Neglect can lead to malfunctions, causing unexpected downtime. Regular checks on oil levels and tire wear can save time and money.

**Tip:** Keep a log of maintenance activities. This helps track performance over time. It can also aid in identifying patterns that require attention.

Top Power Heavy Equipment Machines for Your Construction Needs

| Machine Type | Function | Typical Use | Operating Weight (lbs) | Engine Power (HP) |

|---|---|---|---|---|

| Excavator | Earth digging and moving | Excavating trenches, foundations | 15,000 - 100,000 | 40 - 500 |

| Bulldozer | Grading and pushing | Site clearing, grading | 20,000 - 80,000 | 60 - 500 |

| Loader | Material handling and loading | Loading trucks, material transport | 10,000 - 40,000 | 50 - 200 |

| Crane | Lifting and moving heavy objects | Construction sites, industrial work | 20,000 - 300,000 | 100 - 600 |

| Backhoe | Digging, lifting, and moving | Landscaping, utility installation | 10,000 - 15,000 | 50 - 100 |

Top Brands and Models in Heavy Equipment for Construction

When choosing heavy equipment for construction, it's vital to know the top brands and models. Each brand often focuses on specific functionalities. Some excel in excavators, while others shine with bulldozers. Understanding these details can save you time and money.

For example, certain models are known for their fuel efficiency, which is crucial. Others may have limitations on their lifting capacity, which can affect project timelines. Evaluating specifications helps one make informed choices. A machine that’s perfect for one task may not suit another. This can lead to unnecessary expenses.

It's important to note that not every model will meet every need. Sometimes, even the top brands may fall short in certain areas. Conducting thorough research is essential. Feedback from users can reveal strengths and weaknesses. Make sure to consider your project requirements carefully.

Factors to Consider When Selecting Heavy Equipment

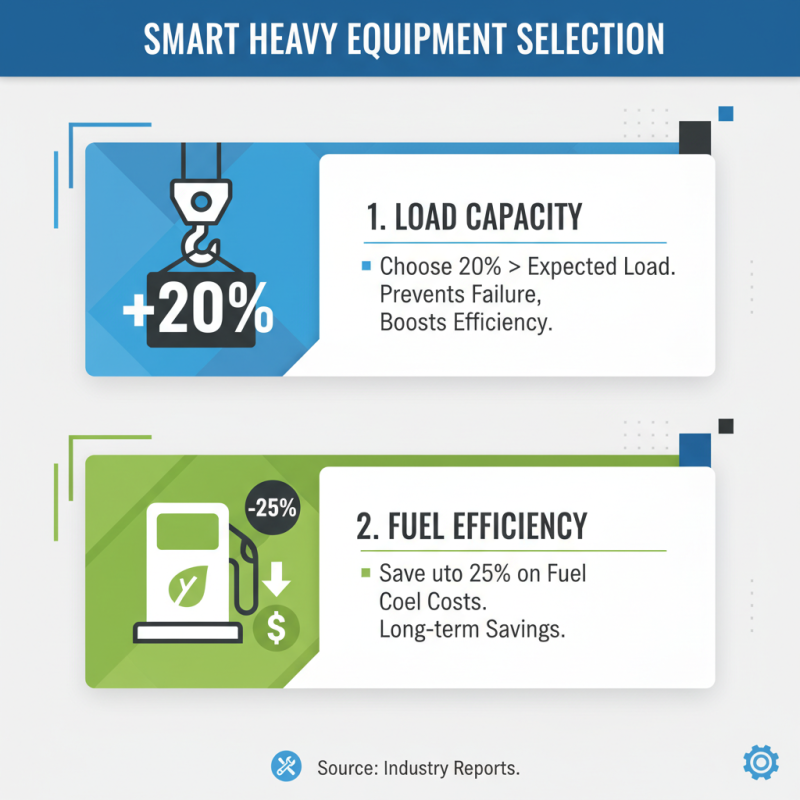

When selecting heavy equipment for construction, several factors must be considered. A key aspect is the load capacity. According to industry reports, choosing equipment that can handle at least 20% more than the expected load is wise. This prevents mechanical failures and improves efficiency. Equipment should also be evaluated for its fuel efficiency. An average construction site can see fuel costs soar to 25% of total expenses. Opting for machines that offer better fuel economy can lead to substantial savings over time.

Another crucial factor is the terrain of the job site. Some heavy machinery is designed for specific environments. For instance, wheeled equipment may struggle on soft ground while tracked machines excel in adverse conditions. It's vital to assess your site thoroughly before purchasing or renting equipment. Safety is equally important. Reports indicate that improper equipment can lead to accidents, with nearly 20% of workplace injuries occurring in construction. Investing in reliable safety features is not just a regulatory necessity; it's crucial for protecting your workforce. Balancing these elements helps ensure that the right equipment is selected for each unique construction need.

Maintenance and Safety Practices for Heavy Equipment Usage

Heavy equipment is vital in construction, yet its maintenance is often overlooked. According to a report by the Association of Equipment Management Professionals, 30% of equipment failures result from poor maintenance. Regular checks can prevent costly downtime. Operators should conduct daily inspections: checking fluid levels, tire pressures, and hydraulic systems is essential.

Safety practices are equally important. According to OSHA, nearly 80% of equipment-related accidents stem from improper operation or lack of training. Workers must be trained. They should know how to operate machines safely and understand the equipment's limitations. Protective gear is not optional; it is essential.

Overconfidence can lead to mistakes. Operators may skip checks, thinking they know their machines. This is risky. Increasing awareness about the need for proper maintenance and safety can save lives and money. Regular training sessions are recommended. They keep safety at the forefront of daily operations. Investing in training and maintenance pays off in the long run.

Top Power Heavy Equipment Machines for Your Construction Needs

This chart displays the average maintenance costs and safety incidents for various heavy equipment machines used in construction. Regular maintenance and adherence to safety practices are crucial for the effective operation of these machines.

Related Posts

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

Top Large Construction Equipment Trends to Watch in 2025

-

Top Power Heavy Equipment Types for Your Construction Needs

-

Top 10 Innovative Construction Equipment for 2024: Boost Efficiency by 30%!

-

How to Choose the Right Machinery Moving Equipment for Your Needs

-

How to Choose the Best Electric Construction Equipment for Your Projects