Top 10 Heavy Equipment Tips Every Operator Needs to Know

In the world of heavy equipment, operating machinery safely and efficiently is paramount. According to Robert Thompson, a veteran heavy equipment operator and industry consultant, "The foundation of effective heavy equipment operation lies in understanding both the machine and the environment in which it works." This insight highlights the critical nature of knowledge and preparedness for operators in this demanding field.

The heavy equipment industry encompasses a variety of machinery used in construction, mining, and other labor-intensive sectors. With the increasing complexity of these machines, it becomes essential for operators to stay informed about the latest operational techniques, safety protocols, and maintenance practices. Mastering these elements not only ensures their own safety but also enhances productivity and reduces operational costs.

As we explore the top ten heavy equipment tips every operator needs to know, we will delve into best practices that seasoned professionals swear by. From pre-operation inspections to understanding load capacity and job site awareness, these crucial tips will equip operators with the necessary tools to excel in their roles and uphold the high standards of the heavy equipment industry.

Essential Pre-Operation Checks for Heavy Equipment Operators

Heavy equipment operators play a critical role in various industries, and ensuring the reliability and safety of their machinery is paramount. Pre-operation checks are essential, particularly for machines like vibratory rollers, which, due to their relatively low-maintenance nature, may often be overlooked. Operators should routinely inspect hydraulic systems, belts, and the condition of the drum to avoid costly breakdowns during critical tasks. According to industry reports, nearly 30% of equipment failures stem from inadequate pre-operation checks, underscoring the importance of thorough inspections.

In colder climates, winter safety inspections become especially vital. Operators should check battery performance, engine fluids, and tire conditions to minimize the risk of equipment failure during harsh weather. A proactive approach, such as performing daily checks and addressing any irregularities immediately, can significantly prolong equipment lifespan. As highlighted in recent studies, consistent pre-operation inspections can lead to a decrease in downtime by up to 40%, enhancing operational efficiency and safety. Regular maintenance not only benefits the equipment but also protects the operator and crew, ensuring a safer working environment.

Understanding Safety Protocols and Personal Protective Equipment

Understanding safety protocols and personal protective equipment (PPE) is crucial for anyone operating heavy machinery. These safety measures are not just guidelines; they are essential practices that can prevent accidents and save lives. Operators should always begin by familiarizing themselves with the specific safety protocols related to the equipment they are handling. This includes understanding operational limits, emergency procedures, and hazard recognition. Proper training is imperative, as it equips operators with the knowledge needed to anticipate and mitigate risks associated with heavy equipment.

In addition to understanding safety protocols, operators must consistently use the appropriate personal protective equipment. This includes hard hats, gloves, high-visibility clothing, and eye protection, specifically designed to shield against the hazards present in construction and heavy machinery environments. Ensuring that all gear is in good condition and fits correctly is equally important. Regular safety assessments should be conducted to reinforce the use of PPE and adjust to any changes in the work environment or regulations. By adhering to established safety protocols and utilizing proper protective gear, operators can significantly reduce the likelihood of injuries and enhance workplace safety.

Techniques for Efficient Equipment Operation and Fuel Management

Effective equipment operation is essential for maximizing efficiency and minimizing fuel consumption in heavy machinery. One key technique is to perform regular maintenance checks before starting any operation. Ensuring that components like filters, fluids, and tires are in optimal condition helps prevent breakdowns and delays, which can lead to increased fuel usage. Operators should also familiarize themselves with the machinery to understand its capabilities and limitations, allowing them to make informed decisions during operation that can conserve fuel and improve productivity.

Another critical aspect of fuel management is adopting smooth and steady operating behaviors. Sudden acceleration and harsh braking not only increase fuel consumption but also wear down the machinery faster. Operators should aim to maintain a consistent speed, especially when transporting loads, which further reduces fuel expenditure. Additionally, utilizing technology such as telematics can provide valuable insights into fuel usage trends, enabling operators to adjust their practices for better efficiency. By prioritizing these techniques, operators can ensure that they are not only effective in their tasks but also contribute to sustainable fuel management practices.

Best Practices for Regular Maintenance and Inspections

Regular maintenance and inspections of heavy equipment are essential for ensuring optimal performance and longevity. Operators should establish a routine checklist that includes checking fluid levels, inspecting hoses for leaks, and confirming that all safety equipment is functional.

By keeping a close watch on these basic components, operators can prevent minor issues from escalating into major problems that could lead to costly downtime.

Additionally, it's crucial to conduct thorough inspections before and after equipment use. Operators should look for signs of wear and tear on critical parts such as tracks, belts, and brakes. Documenting these findings in maintenance logs not only helps track the condition of the equipment but also complies with safety regulations. Investing time in these practices not only enhances safety on the job site but also maximizes the equipment's lifespan, ultimately leading to increased productivity and reduced operational costs.

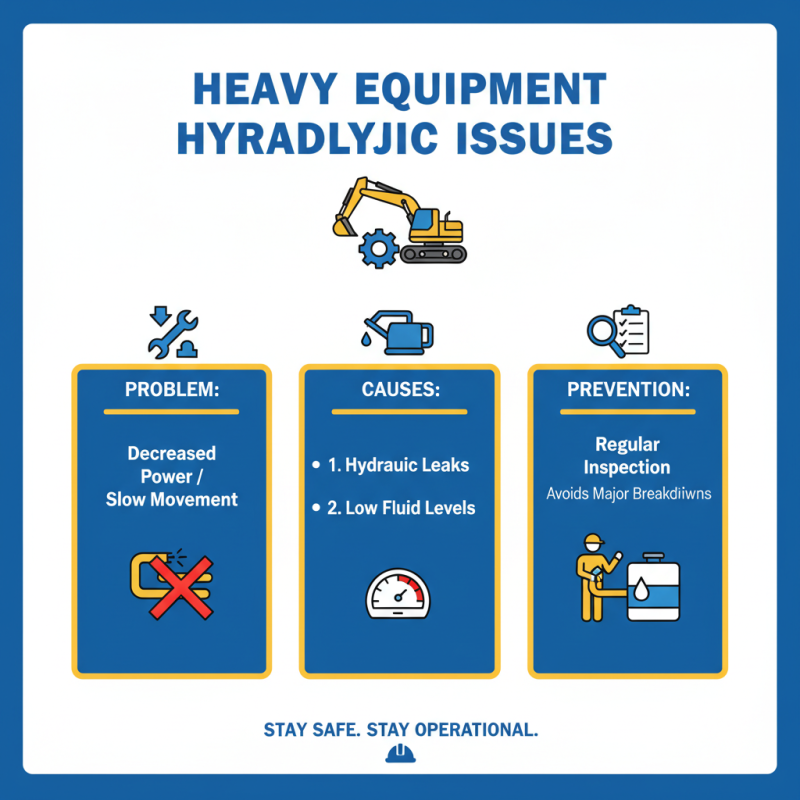

Troubleshooting Common Heavy Equipment Problems on Site

When operating heavy equipment, it's crucial to be prepared for common problems that may arise on site. One frequent issue operators face is hydraulic system malfunctions. If you notice a decrease in power or slow movements, check for leaks in the hydraulic lines or low fluid levels. Regularly inspecting these components can prevent a simple problem from escalating into a major breakdown.

Another common challenge is electrical failure. If the machinery doesn’t start or responds sluggishly, the battery or wiring could be at fault. Ensure that battery connections are tight and corrosion-free. Additionally, keep an eye on warning lights; they often provide the first indication of a malfunction. By familiarizing yourself with these troubleshooting techniques, operators can quickly address issues that may hinder productivity and keep the equipment running smoothly.

Related Posts

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Exploring the Future of Machinery and Equipment: Innovations That Will Transform Industries

-

How to Choose the Right Machinery Equipment for Your Industrial Needs

-

Top 10 Equipment Construction Techniques to Boost Project Efficiency

-

Why Earth Moving Equipment is Essential for Modern Construction Projects

-

How to Choose the Right Machinery Moving Equipment for Your Needs