Top 10 Heavy Construction Equipment Types You Need to Know?

Heavy construction equipment is essential in the construction industry. In 2022, the global market size for heavy construction equipment reached approximately $193 billion. This market is projected to grow significantly in the coming years. Increased urbanization and infrastructure development are driving this growth.

Among the various types of heavy construction equipment, excavators, bulldozers, and cranes play vital roles. These machines enhance productivity and safety on job sites. However, the complexity of these machines often leads to challenges in maintenance and operation. Many operators lack sufficient training, which can result in costly mistakes.

The need for efficiency also raises questions about sustainability. Heavy construction equipment contributes to greenhouse gas emissions. Balancing productivity with environmental responsibility is critical. Reflecting on these challenges, the industry must adapt to new technologies and practices. Understanding the different types of heavy construction equipment can pave the way for better decision-making and improved project outcomes.

Top 10 Heavy Construction Equipment Types You Need to Know

When diving into the world of heavy construction equipment, it’s crucial to understand the essentials. Heavy machinery plays a vital role in shaping our infrastructure. Think about excavators, for instance. These machines are incredible digging tools, but they can also be tricky to operate safely. Careful training is essential, as the risk of accidents still exists.

Another important type is the bulldozer. Their powerful blades can push massive amounts of earth. Yet, while they are strong, visibility can be limited for operators. They need to stay aware of their surroundings. Cranes, on the other hand, are impressive in their ability to lift heavy loads. However, anchoring and stability are major concerns; a small oversight can lead to disastrous results.

Lastly, consider the role of loaders. They are handy for moving materials around. But they often leave behind uneven surfaces. Addressing these challenges can be daunting but necessary for smooth construction processes. Embracing and reflecting on these complexities is key to mastering heavy construction equipment.

Understanding the Role of Excavators in Modern Construction Projects

Excavators play a vital role in modern construction projects. These powerful machines are equipped with a large bucket, allowing for efficient digging and moving of materials. They can handle a variety of tasks, from trenching to demolition. Their versatility makes them a top choice for many construction sites.

The design of an excavator ensures it can operate in tight spaces. This is particularly useful in urban areas where construction sites are limited. However, maneuvering these machines can be challenging. Operators need training to avoid accidents and maximize efficiency. Mistakes can lead to costly delays.

Excavators can also be outfitted with different attachments. These attachments enhance their capabilities, enabling specialized tasks. Despite the advanced technology, there are still issues to consider. Regular maintenance is essential to prevent breakdowns. Failing to keep up can lead to unexpected downtime and expenses. Understanding these machines and their role is crucial for any construction professional.

Top 10 Heavy Construction Equipment Types You Need to Know

| Equipment Type | Main Use | Key Features | Typical Operating Weight |

|---|---|---|---|

| Excavator | Digging and Earth Moving | Articulated arm, various attachments | 10,000 - 100,000 lbs |

| Bulldozer | Land Clearing | Heavy blade, track-driven | 20,000 - 80,000 lbs |

| Backhoe Loader | Excavation and Loading | Front loader and rear excavator | 14,000 - 20,000 lbs |

| Crane | Lifting Heavy Loads | Telescopic boom, tower, or mobile | 10,000 - 1,000,000 lbs |

| Loader | Material Handling | Front-mounted bucket | 5,000 - 30,000 lbs |

| Dump Truck | Transporting Materials | Open-box design for dumping | 15,000 - 40,000 lbs |

| Grader | Leveling Ground | Long blade, adjustable height | 20,000 - 40,000 lbs |

| Paver | Laying Asphalt | Controlled material flow | 10,000 - 50,000 lbs |

| Compactor | Soil and Asphalt Compaction | Vibratory plates or rollers | 1,000 - 30,000 lbs |

The Importance of Bulldozers: Power and Versatility in Earth Moving

Bulldozers are essential in heavy construction. Their power and versatility make them a favorite for earth-moving tasks. A bulldozer's large blade can push massive amounts of soil and debris. This capability is vital for grading, excavation, and site preparation. The compact size allows for maneuverability in tight spaces. Yet, many operators neglect routine maintenance.

Understanding how to operate a bulldozer is crucial. Operators should have training to maximize efficiency. Improper use can lead to equipment damage. Regularly check the blade's sharpness. A dull blade can slow down work. Ensure that all mechanical parts are in good condition too.

Tips for using a bulldozer effectively include maintaining a steady speed. Quick movements can destabilize the machine. Use the right technique for pushing materials. Engage the blade slowly for better control. Always be aware of your surroundings. Other workers may be nearby. Communication on-site is key for safety. With careful operation, bulldozers can significantly enhance productivity in construction projects.

Cranes: Essential for Lifting and Placing Heavy Materials Safely

Cranes play a vital role in heavy construction. They are essential for lifting and placing heavy materials safely. Different types of cranes exist, each designed for specific tasks. Tower cranes, for example, are used for tall buildings. Their height allows them to lift materials to great elevations, but they require careful assembly.

Maintaining cranes is crucial. Operators need training to handle these powerful machines effectively. Errors can lead to accidents. Regular inspections can help prevent malfunctions. It's important to ensure that all components are in good condition. Yet, as sites grow complex, it can be easy to overlook smaller details.

Using cranes requires teamwork. Communication among workers is key to safe operations. Hand signals or radios can help coordinate movements. Miscommunications can result in serious risks on site. Attention to detail matters in every lift. A small mistake can have large consequences, highlighting the need for constant vigilance.

Dump Trucks: Key Players in Material Transportation on Construction Sites

Dump trucks play a vital role in construction sites. They are not just vehicles; they are essential tools for transporting materials. These trucks carry gravel, sand, and dirt. Their powerful engines allow them to move heavy loads efficiently. However, drivers must be skillful. Maneuvering through tight spaces is often a challenge.

The dump truck's design offers flexibility. The bed can pivot to unload materials quickly. Yet, this feature requires precision. Unloading too close to the edge can lead to spills. Workers need to watch for safety. Heavy materials can cause hazards.

Maintenance is crucial for dump trucks. Regular checks on brakes and hydraulics are necessary. Neglect can result in costly repairs or unsafe conditions. Proper training for operators enhances safety on site. In some cases, inexperienced drivers make mistakes. These errors can slow down projects significantly. Each of these factors shows the importance of dump trucks in construction, but they also highlight areas for improvement.

Conclusion

Heavy construction equipment plays a vital role in modern construction projects, significantly enhancing efficiency and safety on job sites. Among the top ten essential types, excavators lead the way with their ability to dig, lift, and move materials with precision. Following closely, bulldozers offer unmatched power and versatility for earthmoving tasks, while cranes are indispensable for safely lifting and placing heavy materials.

Additionally, dump trucks serve as key players in the transportation of various materials, making logistical operations smoother. Loaders contribute to effective material handling, ensuring that loading operations are carried out efficiently. Together, these types of heavy construction equipment form the backbone of any successful construction project, enabling teams to work effectively and meet project deadlines without compromising safety.

Related Posts

-

Top Power Heavy Equipment Types for Your Construction Needs

-

Top Power Heavy Equipment Machines for Your Construction Needs?

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

Top 10 Innovative Construction Equipment for 2024: Boost Efficiency by 30%!

-

Top Large Construction Equipment Trends to Watch in 2025

-

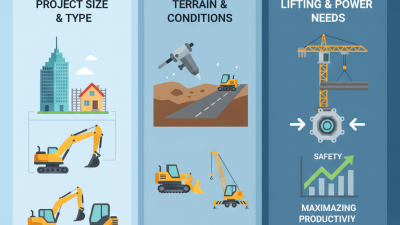

How to Choose the Right Heavy Equipment for Your Construction Project