Top Power Heavy Equipment Types for Your Construction Needs

In the ever-evolving landscape of construction, the utilization of power heavy equipment stands as a critical factor in enhancing productivity and operational efficiency. According to a report by Grand View Research, the global construction equipment market size was valued at approximately $162 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. This growth underscores the importance of selecting the right heavy equipment to meet diverse construction needs, ranging from excavation and earthmoving to lifting and transportation tasks.

Power heavy equipment includes a wide range of machinery essential for various construction processes. According to the Research and Markets report, excavators, loaders, and cranes are among the top equipment types that facilitate significant time and cost savings on job sites. Additionally, advancements in technology have led to the development of more efficient and environmentally friendly models, making it crucial for construction firms to invest in the latest power heavy equipment to stay competitive in the industry. Understanding the core types of equipment available and their applications can greatly influence project success and return on investment.

Understanding the Importance of Heavy Equipment in Construction

Heavy equipment plays a critical role in the construction industry, serving as the backbone for a variety of projects ranging from residential buildings to large infrastructure developments. Understanding the importance of such machinery is essential for construction professionals, as these tools significantly enhance efficiency, safety, and productivity on job sites. With the use of heavy equipment, complex tasks such as excavation, material handling, and demolition can be executed with precision and speed, ultimately reducing the time required to complete projects.

Moreover, heavy equipment contributes to improved safety standards on construction sites. The use of advanced machinery mitigates the physical demands placed on workers, thus decreasing the risk of injury. For example, excavators and cranes allow operators to move large amounts of material without the manual labor typically required. This mechanization not only protects the workforce but also ensures that projects adhere to timelines and regulations.

As the construction industry continues to evolve, the integration of modern heavy equipment remains a vital component in meeting the ever-growing demands for efficiency and safety in construction processes.

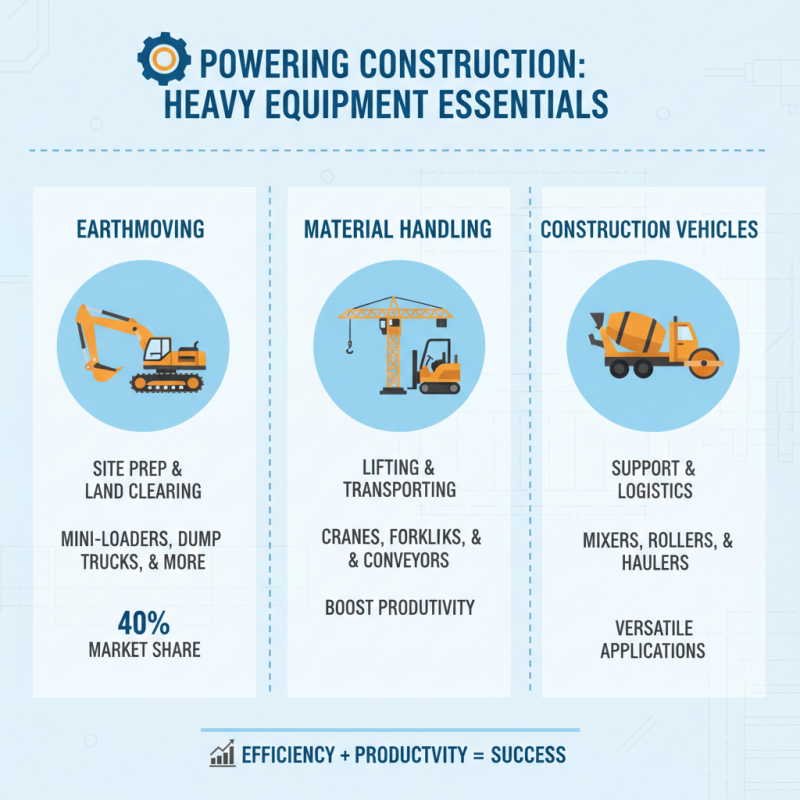

Categories of Power Heavy Equipment Used in Construction Projects

When it comes to construction projects, the range of power heavy equipment available can make a significant difference in efficiency and productivity. The primary categories of heavy equipment utilized include earthmoving equipment, material handling equipment, and construction vehicles. According to a report by the Global Construction Equipment Market, earthmoving equipment alone accounts for about 40% of the total heavy equipment market share, indicating its crucial role in site preparation and land clearing.

Earthmoving equipment includes bulldozers, excavators, and backhoes, which are essential for tasks such as grading, trenching, and demolition. These machines enhance productivity by expediting the movement of soil and materials, reducing manual labor. Material handling equipment, such as forklifts and cranes, facilitates the transportation and placement of heavy materials, making them indispensable in the construction workflow. The market for material handling equipment is projected to grow substantially, driven by the rising demand for efficient logistical operations on construction sites.

In addition to these, construction vehicles like dump trucks and concrete mixers play a vital role in the overall construction ecosystem. Data from the Construction Equipment Guide indicates that the demand for these vehicles continues to rise, particularly in urban areas where space and time efficiency are paramount. Understanding these categories of power heavy equipment empowers construction professionals to choose the right tools for their specific project needs, ultimately leading to enhanced operational effectiveness and project outcomes.

Key Features to Consider When Choosing Construction Equipment

When selecting heavy equipment for construction, it's essential to focus on key features that align with the specific needs of your projects. According to the Equipment Leasing and Rental Association (ELRA), the U.S. construction equipment market is projected to reach $63 billion by 2025, highlighting the growing demand for reliable machinery. One critical feature to consider is the equipment's versatility. Multi-functional machines can reduce costs by minimizing the number of different pieces of equipment required on-site, allowing for a more streamlined operation.

Another significant consideration is the equipment's fuel efficiency and emissions output. The Environmental Protection Agency (EPA) reports that construction equipment accounts for nearly 30% of greenhouse gas emissions in the industry. Selecting equipment that adheres to the latest emissions standards can not only help mitigate environmental impact but also reduce operational costs over time. Additionally, tracking advancements in telematics technology can provide construction companies with real-time data on equipment usage, enhancing efficiency and lowering maintenance expenses.

Safety features also play a crucial role in equipment selection. The Occupational Safety and Health Administration (OSHA) emphasizes that construction sites are among the most hazardous working environments. Therefore, choosing equipment equipped with safety systems, such as automatic shut-offs and advanced operator controls, can significantly reduce the risk of accidents. As the construction sector continues to evolve, investing in equipment that incorporates these key features will not only enhance productivity but also ensure a safer working environment.

Top Power Heavy Equipment Types for Your Construction Needs

Top Brands and Models of Heavy Equipment for Various Needs

When it comes to selecting heavy equipment for construction projects, understanding the top brands and models available can greatly enhance productivity and efficiency. Different types of heavy machinery cater to distinct requirements, from earthmoving to lifting and material handling. For excavation needs, powerful and durable excavators stand out, offering various bucket sizes and attachments to accommodate different soil types and project scales.

Similarly, wheel loaders are invaluable for transporting bulk materials quickly and efficiently, making them a staple on construction sites.

In the realm of lifting, telehandlers and cranes come into play, each offering unique advantages based on the project specifics. Telehandlers are versatile machines that excel in tight spaces, capable of reaching heights while providing significant load capacity. On the other hand, cranes, with their extensive reach and lifting capabilities, are essential for heavy lifting tasks and complex structural projects.

Other critical heavy equipment types include bulldozers for land clearing and compactors for soil density management. Selecting the right combination of these heavy equipment types can significantly impact project timelines and execution quality.

Maintenance Tips for Ensuring Longevity of Construction Equipment

Maintaining heavy construction equipment is crucial for ensuring its longevity and optimal performance. Regular inspections should be a part of your maintenance routine, focusing on critical components such as hydraulic systems, engines, and undercarriages. Identifying wear and tear early can prevent more significant issues down the line. Additionally, it’s essential to keep machinery clean, as dirt and debris can lead to premature breakdowns. Developing a consistent cleaning schedule, especially after heavy usage, will help protect your equipment and enhance its lifespan.

Proper lubrication also plays a vital role in the maintenance of construction machinery. All moving parts need adequate lubrication to minimize friction and wear. Understanding the recommended lubrication intervals for various components is key—this ensures that every part operates smoothly, thereby extending the operational life of your equipment. Moreover, monitoring fluid levels, such as oil and coolant, is necessary to prevent overheating and mechanical failures. By adhering to these maintenance tips, you can maximize the efficiency and reliability of your heavy equipment, ensuring it meets your construction needs for years to come.

Related Posts

-

How to Choose the Right Excavation Equipment for Your Project Needs

-

How to Choose the Right Heavy Equipment for Your Construction Project

-

Top 10 Heavy Equipment Tips Every Operator Needs to Know

-

Best 10 Tractors and Equipment for Every Farming Need

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

Top Large Construction Equipment Trends to Watch in 2025