What is Moving Industrial Equipment? Key Insights and Effective Strategies

Moving industrial equipment is a complex yet essential process that plays a crucial role in many manufacturing and logistics operations. As industries grow and evolve, the need for efficient relocation of machinery becomes increasingly important for optimizing workflow, enhancing productivity, and reducing operational downtime. From heavy machinery in factories to precision instruments in laboratories, the challenge of moving industrial equipment requires careful planning, strategic execution, and a comprehensive understanding of the specific requirements involved.

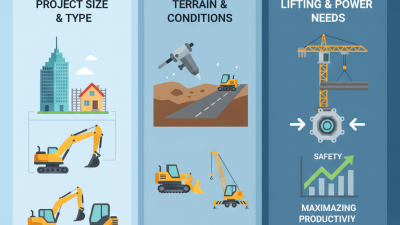

In this exploration, we will delve into key insights about moving industrial equipment, highlighting the factors that influence successful relocations. This includes an assessment of the equipment’s size, weight, and fragility, as well as the importance of proper handling techniques and tools. Additionally, we will discuss effective strategies that businesses can implement to streamline the moving process, minimize risks, and ensure that equipment is transported safely and efficiently.

By understanding the intricacies of moving industrial equipment, organizations can not only mitigate potential disruptions but also lay a foundation for future growth and innovation. This introduction sets the stage for a deeper examination of the best practices and considerations that accompany the moving of essential industrial assets.

Understanding Moving Industrial Equipment: Definition and Scope

Moving industrial equipment refers to the process of relocating heavy machinery and tools used in various manufacturing and production facilities. This can encompass everything from conveyor belts and assembly lines to large-scale factory machines. The scope of moving industrial equipment includes not only the physical transfer of the items but also the planning, execution, and safety measures taken during the process. Understanding the definition and scope is crucial for companies engaged in manufacturing, as improper handling can lead to significant downtime and costly damages.

The process of moving industrial equipment involves several critical steps. Initially, a detailed assessment of the equipment and its new location is necessary to determine the best methods for safe transportation. This includes evaluating the weight and dimensions of the equipment, identifying potential hazards, and planning for any required disassembly or reassembly. Furthermore, effective strategies involve using specialized tools and techniques to ensure safe handling, such as rigging techniques and transport equipment. In addition, employing trained personnel who are familiar with safety protocols is essential to minimize risks associated with moving heavy machinery.

Key Considerations When Planning for Industrial Equipment Relocation

Relocating industrial equipment is a complex process that requires meticulous planning and consideration. One of the key factors to take into account is the physical dimensions of the equipment being moved. According to a report by the Industrial Moving Association, nearly 65% of relocation projects encounter delays due to underestimating the logistical challenges posed by large machinery. This includes the need for specialized transportation vehicles, rigging equipment, and skilled labor who can navigate obstacles such as tight spaces and weight restrictions. Properly mapping out the layout of both the current and new locations can facilitate a smoother transition.

Another critical consideration is the impact of downtime on production capabilities. A study by the National Association of Manufacturers found that unplanned downtime can cost companies up to $5,000 per hour. Therefore, developing a comprehensive relocation timeline that minimizes operational disruptions is essential. This can involve scheduling the move during off-peak hours or over weekends, ensuring that production can resume promptly. Incorporating contingency plans for potential setbacks further safeguards against unforeseen challenges, allowing businesses to maintain efficiency during the transition.

Effective Strategies for Safely Transporting Heavy Machinery

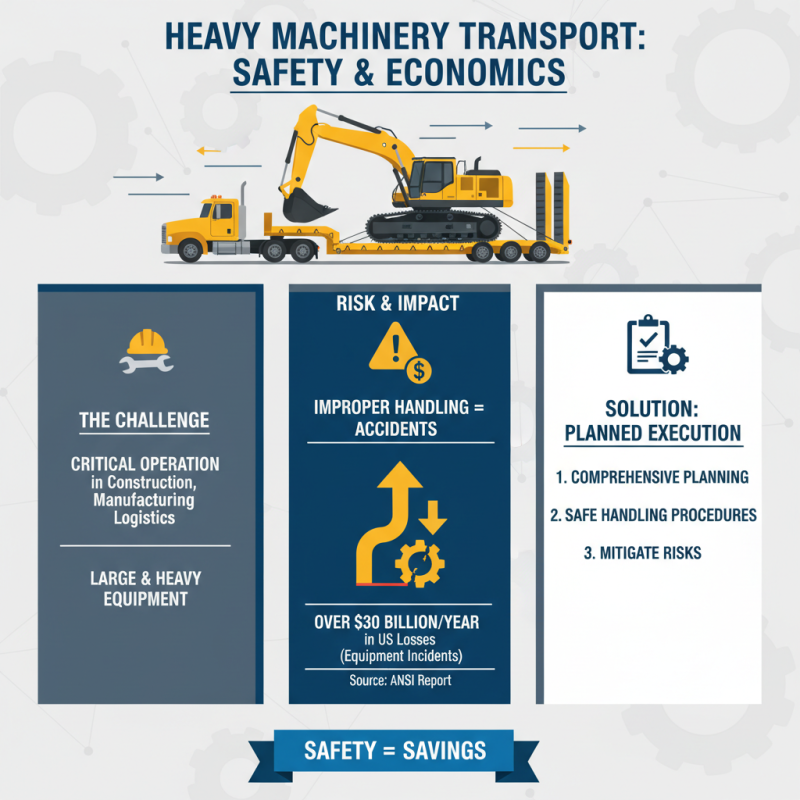

Transporting heavy machinery is a critical operation in various industries, including construction, manufacturing, and logistics. Safe and effective transportation of industrial equipment requires comprehensive planning and execution to mitigate risks associated with moving large and heavy equipment. According to a report by the American National Standards Institute (ANSI), improper handling of industrial equipment can lead to significant financial losses, with accidents resulting in over $30 billion annually in the U.S. alone due to equipment-related incidents.

One of the most effective strategies for safely transporting heavy machinery is thorough preparation. This involves creating a detailed logistics plan that includes analyzing the dimensions and weight of the equipment, assessing the transport route for potential obstacles, and selecting appropriate handling equipment. A report from the Occupational Safety and Health Administration (OSHA) highlights that proper training and certification of personnel involved in moving heavy machinery can reduce accidents by up to 40%. Additionally, utilizing technology such as load monitoring systems can provide real-time data to ensure the safe transport of machinery, enhancing overall safety measures.

Furthermore, it's essential to employ specialized transport vehicles designed for heavy loads, equipped with features such as low ground clearance and appropriate weight distribution systems. The freight transport market for heavy machinery is projected to grow, increasing the demand for safer and more efficient transportation methods. Industry experts recommend conducting regular maintenance checks on transport vehicles and assessing the integrity of securing mechanisms used during transport. By implementing these strategies and adhering to industry standards, businesses can significantly reduce the risks associated with moving industrial equipment, ensuring both safety and efficiency.

Industry Best Practices: Minimizing Downtime During Equipment Moves

Minimizing downtime during the relocation of industrial equipment is crucial for maintaining productivity and efficiency in manufacturing processes. One effective strategy is to plan the move meticulously. Understanding the layout of both the current and new facilities helps in optimizing the movement process. Involve your team early in the planning stages to identify potential challenges and develop a clear timeline to guide the move.

Tips: Always create a detailed inventory of the equipment to be moved, including specifications and any special requirements. This inventory will aid in tracking items during the transition and ensure nothing is lost or damaged. Additionally, consider conducting a trial run of the move within a controlled environment, allowing your team to identify bottlenecks and address them before the actual relocation.

Another vital aspect is ensuring all staff is trained and prepared for the move. By facilitating training sessions on equipment handling and safety protocols, you can prevent accidents and reduce the time spent troubleshooting issues during the actual transition. Encouraging open communication among team members can also provide a platform for addressing concerns and streamlining the moving process, thereby minimizing downtime and promoting a smoother operation.

Case Studies: Successful Industrial Equipment Relocation Examples

Relocating industrial equipment can present a myriad of challenges, but there are several case studies that highlight successful strategies employed by various companies. One striking example is a manufacturing firm that relocated its heavy machinery to a new facility to expand production capabilities. The planning process involved a thorough assessment of the machinery, which included measurements and weight calculations, to ensure that the new facility could accommodate the equipment safely. The team developed a detailed timeline and allocated resources effectively, which resulted in the relocation being completed ahead of schedule without incident.

Another notable case involved an energy sector company transitioning its equipment to a more technologically advanced site. The strategy focused on a phased approach to minimize downtime. The team implemented a comprehensive risk management plan, identifying potential obstacles and preparing mitigation strategies. They also engaged in extensive employee training, ensuring that all personnel were familiar with the new equipment and processes. This emphasis on preparation and communication led to a seamless transition, allowing the company to resume operations faster than anticipated while enhancing overall productivity.

Related Posts

-

How to Choose the Right Machinery Equipment for Your Industrial Needs

-

Why Earth Moving Equipment is Essential for Modern Construction Projects

-

How to Choose the Right Heavy Equipment for Your Construction Project

-

How to Choose the Right Machinery Moving Equipment for Your Needs

-

Top Large Construction Equipment Trends to Watch in 2025

-

Top 10 Innovative Construction Equipment for 2024: Boost Efficiency by 30%!