Top Large Construction Equipment Trends to Watch in 2025

As we venture into 2025, the landscape of the construction industry is poised for significant transformation, largely driven by advancements in large construction equipment. Experts emphasize that staying ahead of these trends is essential for companies aiming to enhance efficiency and productivity on job sites. John McAllister, a leading expert in the field, states, "The evolution of large construction equipment is not just about size, but about smart integration and sustainability that will shape the future of our industry."

In the coming years, we can expect to see key innovations in technology, automation, and environmental considerations in large construction equipment. These advancements promise not only to streamline operations but also to minimize the carbon footprint of construction activities, aligning with global sustainability goals. The adoption of electric and hybrid machinery, improved telematics, and enhanced safety features are just a few areas where significant progress is anticipated.

Moreover, as the demand for skilled labor continues to rise, the role of large construction equipment will increasingly intersect with workforce development and training. Companies that effectively integrate new technologies will undoubtedly have a competitive edge, paving the way for a more productive and sustainable future in construction. The trends we observe today are just the beginning of a remarkable evolution within the realm of large construction equipment.

Emerging Technologies in Large Construction Equipment for 2025

As we look towards 2025, the large construction equipment sector is set to undergo significant transformations, driven by emerging technologies that promise to enhance efficiency, safety, and sustainability. One of the most notable trends is the adoption of automation and robotics in construction machinery. From autonomous bulldozers to robotic cranes, these innovations are aimed at reducing labor costs and minimizing human error on job sites. The integration of machine learning and artificial intelligence is enabling equipment to perform complex tasks with precision, leading to faster project completion times and improved overall productivity.

Another key advancement is the increased use of Internet of Things (IoT) technology within large construction equipment. This connectivity allows for real-time monitoring of machinery, streamlining maintenance schedules, and optimizing operational performance. With sensors embedded in equipment, operators can gain insights into performance data, allowing for proactive interventions before breakdowns occur. Additionally, the data collected can inform better decision-making processes, helping managers allocate resources more efficiently and maximize equipment utilization.

Lastly, sustainability is a driving factor behind the development of new construction technology. Many companies are now focusing on eco-friendly machinery designed to reduce emissions and consumption of resources. Innovations such as hybrid power systems and alternative energy sources are becoming more commonplace, reflecting a growing commitment to environmental responsibility in the construction industry. As a result, 2025 is poised to see not only advancements in capabilities but also a shift towards greener practices that align with global sustainability goals.

Top Large Construction Equipment Trends to Watch in 2025 - Emerging Technologies in Large Construction Equipment for 2025

| Trend | Description | Expected Impact | Technology Type | Adoption Rate (%) |

|---|---|---|---|---|

| Automation and Robotics | Increased use of autonomous machinery to enhance productivity and safety on job sites. | Higher efficiency and reduced labor costs. | Automation | 65% |

| Electric Equipment | Adoption of electric-powered machinery to reduce emissions and comply with environmental regulations. | Lower carbon footprint and operational costs. | Sustainability technology | 50% |

| Telematics | Integration of telematics for real-time monitoring and data analytics of equipment. | Improved maintenance strategies and operational efficiency. | Data Analytics | 75% |

| 3D Printing | Utilization of 3D printing for on-site fabrication of building components. | Reduced waste and faster construction timelines. | Manufacturing technology | 30% |

| Drones | Increased use of drones for site surveying, inspections, and monitoring. | Enhanced data collection accuracy and reduced labor costs. | Aerial technology | 55% |

Sustainability Trends Impacting Construction Equipment Choices

As the construction industry moves towards a more sustainable future, the choice of equipment is increasingly influenced by eco-friendly practices. In 2025, one of the leading trends will be the integration of energy-efficient machinery that minimizes carbon footprint and enhances operational efficiency. This shift not only aligns with global sustainability goals but also meets the growing demand from clients for greener construction solutions. Construction companies are now prioritizing equipment that utilizes alternative energy sources, such as electric or hybrid systems, as well as those designed with recyclable materials.

Another crucial aspect of sustainability in construction equipment is the focus on reducing waste and extending the lifecycle of machinery. Manufacturers are adopting practices that emphasize durability and the ease of maintenance, enabling operators to maximize the functionality of their equipment while minimizing environmental impact. Innovations such as modular design and remanufacturing processes are becoming standard, offering the potential to refurbish old machinery and reduce the need for new resources. These developments not only contribute to a more sustainable construction ecosystem but also provide significant cost savings over time.

The Role of Automation in Shaping Equipment Operations

As we look towards 2025, the construction industry is set to undergo significant transformations, particularly through the integration of automation in equipment operations. Automation technologies are not just enhancing efficiency but are also redefining how construction projects are managed.

Smart equipment equipped with AI and machine learning algorithms can analyze real-time data to optimize performance and improve safety measures onsite, leading to reduced project timelines and costs.

Tips for embracing automation in construction include investing in training for your workforce to adapt to new technologies. Understanding the capabilities of automated machinery allows operators to leverage its full potential, enhancing both productivity and safety. Additionally, consider implementing a phased approach to automation, starting with smaller projects to gauge the effectiveness of the technology before scaling up to larger, more complex operations.

Moreover, collaboration between various stakeholders in the construction process is crucial. Sharing data and insights between equipment manufacturers, contractors, and project managers fosters a more integrated approach to automation. This cooperation can result in customized solutions that meet specific project needs while ensuring that safety and efficiency are prioritized throughout the construction lifecycle.

Cost Efficiency Strategies Through Advanced Machinery in 2025

As we look ahead to 2025, the construction equipment sector is poised for significant evolution, particularly in the realm of cost efficiency. Advanced machinery, driven by technological advancements, promises to lower operational costs while maximizing productivity. According to a report by MarketsandMarkets, the construction equipment market is expected to reach $271 billion by 2025, which highlights the industry's growing emphasis on innovative solutions to tackle traditional cost concerns.

Integrating smart technologies into construction machinery not only boosts performance but also enhances maintenance strategies. Predictive maintenance, which leverages IoT sensors and AI, can reduce downtime by up to 20%, as reported by McKinsey. This approach enables contractors to anticipate equipment failures before they occur, ensuring projects stay on schedule and within budget.

Tips: To take advantage of these advancements, contractors should invest in training their workforce on new technologies. Encouraging staff to stay updated with the latest machinery options can significantly enhance operational efficiency. Additionally, consider exploring equipment leasing options, which can alleviate upfront costs while allowing access to the most advanced tools in the market. Embracing these strategies will be key for construction companies aiming to thrive in a competitive landscape in 2025.

Regulatory Changes Affecting Large Equipment Innovations and Usage

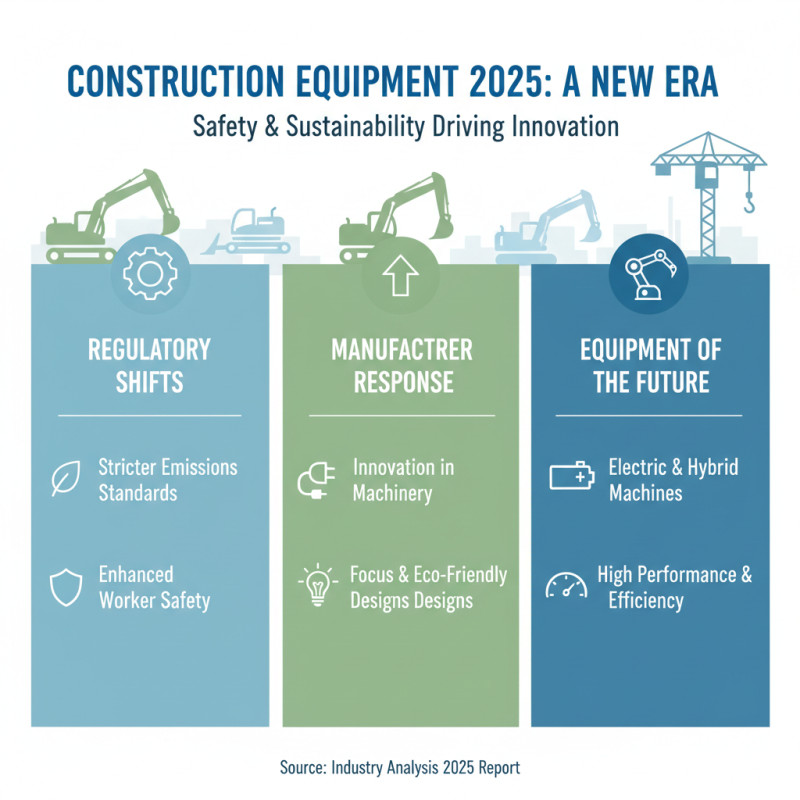

The landscape of large construction equipment is poised for significant transformation in 2025, driven by a series of regulatory changes aimed at enhancing safety and sustainability in the industry. Governments across the globe are implementing stricter emissions standards and safety regulations, which push manufacturers to innovate and create more environmentally friendly and efficient machinery. These regulations not only address the urgent need to reduce greenhouse gas emissions but also emphasize the importance of worker safety on construction sites. As a result, equipment designers are increasingly focusing on developing electric and hybrid machinery that meets these new standards while maintaining high performance.

Moreover, the shift towards digitalization in construction is being influenced by regulatory frameworks that promote transparency and accountability. Enhanced regulations around data reporting and compliance have stimulated the adoption of smart technologies in large construction equipment. This includes the integration of IoT devices and AI capabilities that can monitor equipment performance in real-time, ensuring adherence to safety protocols and regulatory compliance. As these technologies become more prevalent, they will likely reshape how large construction equipment is utilized, providing valuable insights that can lead to improved operational efficiency and better resource management. Thus, staying abreast of these regulatory changes is crucial for stakeholders aiming to thrive in the evolving construction industry.

Related Posts

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

Top 10 Equipment Construction Techniques to Boost Project Efficiency

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Why Earth Moving Equipment is Essential for Modern Construction Projects

-

10 Essential Tips for Maintaining Large Equipment to Maximize Lifespan and Efficiency

-

What is Power Equipment and How to Choose the Right Type for Your Needs