Top Heavy Equipment Types: A Comprehensive Guide for Buyers

In the world of construction and heavy industry, understanding different heavy equipment types is crucial. Renowned expert John Smith once said, "The right heavy equipment can make or break a project." His insight highlights the significance of making informed choices in this sector.

Heavy equipment encompasses a variety of machines used for various tasks. From excavators to bulldozers, each piece serves a specific purpose. Yet, selecting the right type can be a daunting task for buyers. Many aspects must be considered, like project requirements, budget constraints, and the equipment’s durability.

Buyers often overlook the importance of maintenance in their decision-making. A reliable machine requires regular upkeep, which can add to long-term costs. Additionally, the choice of whether to buy or lease can lead to reflection. Ultimately, understanding these nuances can lead to smarter purchasing decisions in the heavy equipment industry.

Heavy Equipment Overview: Understanding the Industry Landscape

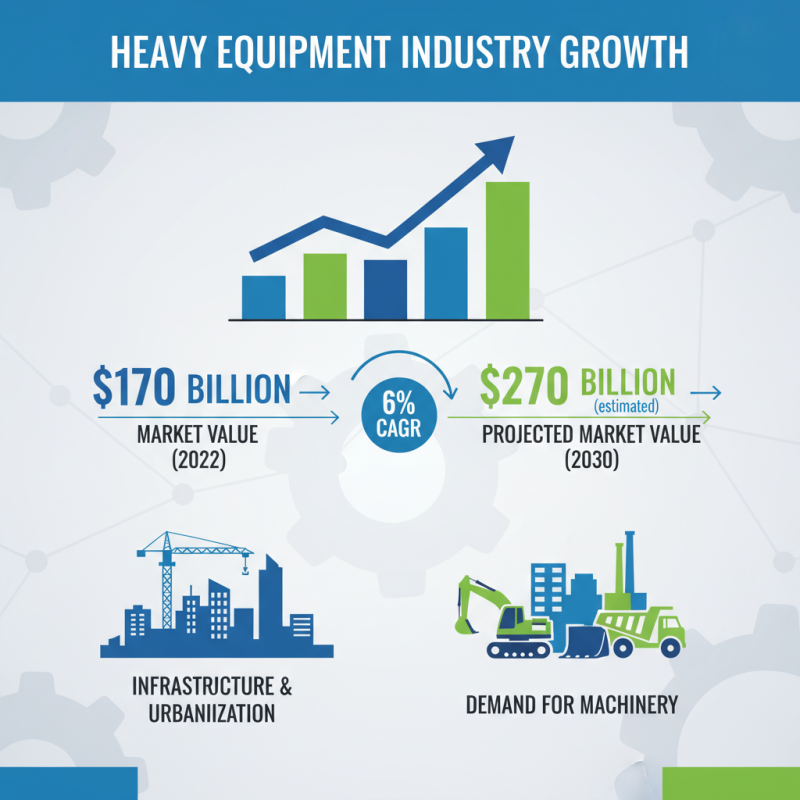

The heavy equipment industry is vast and dynamic. In recent reports, the market was valued at over $170 billion in 2022. It is projected to grow at a compound annual growth rate (CAGR) of nearly 6% until 2030. Several factors contribute to this growth, including infrastructure projects and urbanization. These elements drive demand for various kinds of heavy machinery.

Construction, mining, and agriculture dominate the sector. Construction equipment accounts for about 50% of total sales. Excavators, loaders, and bulldozers are essential in building infrastructure. Mining and agriculture also rely heavily on specialized machinery. Data show that investments in agriculture equipment alone are expected to rise significantly by 2025.

**Tip:** Always assess your specific needs before purchasing heavy equipment. Consider factors like the project scale and budget. This will ensure you choose the right machinery without overspending.

The industry is facing challenges, such as fluctuating material costs and supply chain disruptions. These issues can lead to delays and increased expenses. However, industry players are adapting by leveraging technology. AI and IoT are becoming more common in equipment monitoring and maintenance.

**Tip:** Stay updated on industry trends to make informed decisions. Understanding current challenges can help in planning future investments wisely.

Key Types of Heavy Equipment: A Breakdown of Essential Machines

Heavy equipment plays a crucial role in construction and industrial sectors. Understanding key types of heavy machinery is essential for buyers. Excavators are often at the forefront of these operations. They can handle various tasks, from digging to demolition. According to industry reports, sales of excavators reached over 30 billion dollars in 2022 alone. This figure illustrates a growing demand for these versatile machines.

Another significant category is bulldozers. These powerful machines excel in pushing large quantities of earth across job sites. They are often indispensable in site preparation and grading work. Reports show that bulldozer sales have increased annually by about 5%. However, operators sometimes struggle with the complexities of using these machines effectively. Proper training is vital for maximizing efficiency and safety on job sites.

Loaders also hold an important position in heavy equipment. They are particularly useful for moving materials quickly. Data indicates that wheel loaders made up a large percentage of total heavy equipment sales last year. Despite their effectiveness, buyers frequently overlook maintenance needs. Neglecting regular checks can lead to costly downtime. Heavy equipment selection requires careful consideration of machine types and operational challenges.

Top Heavy Equipment Types: A Comprehensive Guide for Buyers

| Equipment Type | Primary Use | Key Features | Typical Weight (tons) |

|---|---|---|---|

| Excavator | Digging and Excavation | Articulated arm, rotating cabin | 10-50 |

| Bulldozer | Earth Moving | Large blade, powerful tracks | 20-80 |

| Backhoe Loader | Construction and Ditching | Loading bucket and digging arm | 5-15 |

| Crane | Lifting Heavy Materials | Boom for height, hook for lifting | 10-200+ |

| Dump Truck | Transporting Materials | Open bed, hydraulic lift | 10-40 |

| Loader | Material Handling | Front-mounted bucket, high lift | 5-30 |

Factors to Consider When Buying Heavy Equipment

When purchasing heavy equipment, several factors come into play. The initial cost is often crucial. Reports indicate that average equipment costs can range from $10,000 to over $500,000. Buyers need to assess their budget carefully. Financing options can help, but interest rates vary significantly.

Another important aspect is equipment reliability. According to industry surveys, about 30% of buyers experience unplanned downtime. This can lead to significant project delays. Therefore, understanding the equipment's maintenance history is vital. Checking for warranty coverage can also be a deciding factor.

Fuel efficiency is becoming a focal point, especially with rising fuel costs. Statistics reveal that fuel consumption impacts overall operational costs by up to 25%. Buyers should seek models with better fuel economy. Ultimately, weighing these factors carefully can lead to better investment decisions.

Maintenance Tips for Optimal Performance of Heavy Equipment

Maintaining heavy equipment is crucial for its performance. Regular maintenance extends the life of the machine. It also reduces operating costs. Operators should inspect machinery daily. Look for leaks, unusual noises, and wear. These insights can help prevent larger issues.

Tips: Always check the fluid levels before starting. This includes oil, coolant, and hydraulic fluids. Low levels can lead to overheating. It's also beneficial to clean filters regularly. Dirty filters can restrict airflow and damage engines.

Keeping a detailed maintenance log is essential. Note every service performed. This will help track trends and predict future problems. Sometimes, small problems are overlooked. Addressing these early can save time and money later. Heavy equipment requires diligence and proactive measures to perform optimally.

Future Trends in the Heavy Equipment Market: What Buyers Should Know

As the heavy equipment market evolves, buyers must stay informed about upcoming trends. The demand for eco-friendly machinery is increasing rapidly. Manufacturers are exploring electric and hybrid models. These innovations promise lower emissions and fuel costs. Buyers should consider the potential long-term savings. Yet, the initial investment may feel daunting.

Automation is another exciting trend shaping the industry. Remote-controlled and autonomous equipment is gaining traction. Operators can work from safer distances. This reduces risks and enhances productivity. However, training might be necessary to adapt to new technologies. Many professionals may resist this change initially.

Furthermore, the rise of telematics offers valuable insights. Real-time data on equipment performance can lead to better maintenance. Knowing when machinery needs servicing is crucial. Yet, there's an overload of information that can be overwhelming. Buyers need to find a balance between data and intuition. Embracing these future trends can be challenging, but essential for success.

Top Heavy Equipment Types: Market Share Distribution (2023)

Related Posts

-

Top 10 Heavy Equipment Tips Every Operator Needs to Know

-

How to Choose the Right Excavation Equipment for Your Project Needs

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

Top 10 Equipment Construction Techniques to Boost Project Efficiency

-

How to Choose the Right Heavy Equipment for Your Construction Project