What is Excavation Equipment and How Does It Work?

Excavation equipment plays a vital role in construction and mining industries. The global excavation equipment market was valued at approximately $40.6 billion in 2022 and is projected to grow significantly. This rise is driven by urbanization and infrastructure development.

These machines, including excavators, bulldozers, and backhoes, are essential for site preparation, material handling, and demolition. For example, a standard hydraulic excavator can lift and dig several tons of earth in minutes. Furthermore, the efficiency of modern excavation equipment has improved due to advanced technology. Nevertheless, the industry faces challenges, such as the high cost of equipment maintenance and the need for skilled operators.

Understanding how excavation equipment works is crucial. It involves complex mechanics and hydraulics to perform various tasks. Even with innovation, many operators may lack proper training. This gap can lead to accidents or project delays. Addressing these issues will be key for the industry's future.

Types of Excavation Equipment Used in Construction Projects

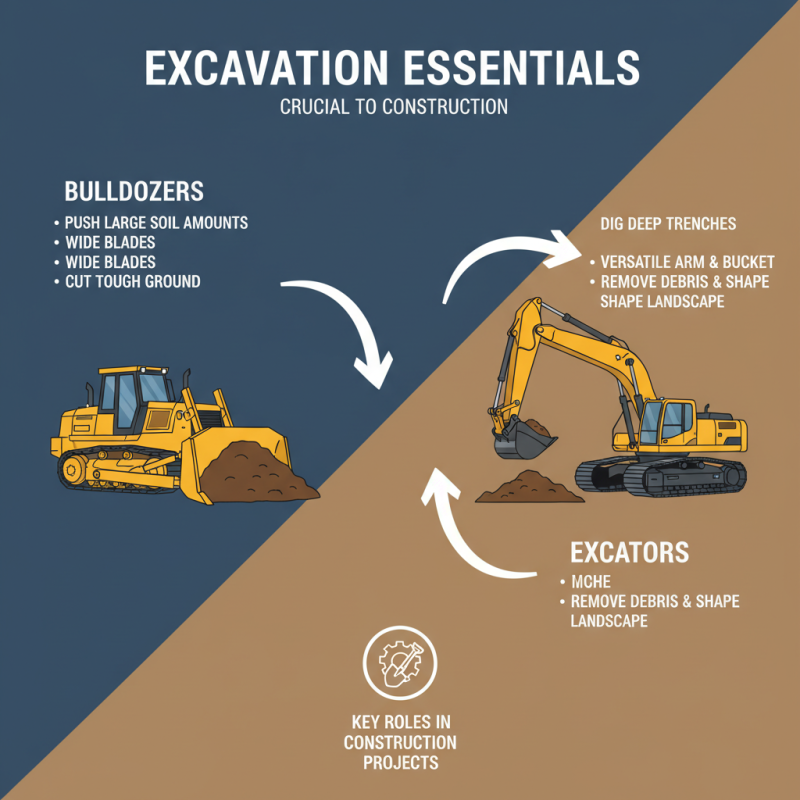

Excavation is a crucial aspect of construction projects. Various types of excavation equipment play significant roles in these tasks. Bulldozers are essential for pushing large amounts of soil. They have wide blades that can cut through tough ground. Excavators come with a long arm and bucket, making them versatile for digging deep trenches. These machines can easily remove debris and help shape the landscape.

Backhoes combine a loader and an excavator. This dual functionality makes them efficient for tasks like digging and lifting. Skid-steer loaders are small but powerful. They are ideal for tight spaces and can move earth swiftly. Compaction equipment ensures that the soil is stable after excavation. Operating these machines requires skill. Mistakes can lead to hazards or project delays.

Finding the right equipment often presents challenges. Not all machines are suitable for every project. It’s essential to assess the site conditions. Using the wrong equipment could cause damage. Therefore, choosing the right tools takes time and consideration. Each piece of equipment has its pros and cons, influencing project outcomes.

Key Components and Features of Excavation Equipment

Excavation equipment plays a crucial role in construction and earthmoving projects. Key components include the bucket, arm, and boom. The bucket is designed to scoop up materials efficiently. It varies in size, depending on project requirements. An average excavator bucket can hold around 0.4 to 1.5 cubic yards of soil.

The arm connects the bucket to the main body of the excavator. This allows for precise movement and control. A standard hydraulic excavator can exert a force of up to 20 tons, depending on its size and design. Hydraulic systems are vital. They manage the machine's movements and improve efficiency by utilizing pressurized fluids.

Beyond mechanics, user training is essential. Improper use can lead to accidents. Reports estimate that human error accounts for about 25% of equipment-related incidents. Regular maintenance is also needed. Neglect can lead to costly repairs or downtime. Operators must remain vigilant to ensure safety and functionality while using excavation equipment.

How Excavation Equipment Operates and Functions

Excavation equipment plays a vital role in construction and landscaping. Various machines are designed to dig, move, and grade earth. From backhoes to bulldozers, each piece has a specific function. A backhoe combines digging and loading tasks efficiently. Its articulated arm allows for precision in tight spaces.

The operation of this equipment requires skilled operators who understand their capabilities. Controls can be complex, with various levers for movement and speed. Training is essential to ensure safety on-site. Improper handling can lead to costly mistakes or accidents.

Understanding how these machines work is crucial. Hydraulic systems power most of the equipment, allowing for heavy lifting and forceful digging. However, these systems can fail if not properly maintained. Regular inspections are a must. Operators should also be aware of environmental impacts, as excavation can cause erosion or habitat destruction.

Safety Measures When Using Excavation Equipment

Using excavation equipment requires careful attention to safety. Heavy machinery can be dangerous if operators do not follow the correct protocols. Always wear personal protective equipment (PPE), such as helmets and gloves. This gear helps protect against falling objects and sharp edges.

Before operating, inspect the machinery. Check for leaks. Ensure all parts are functioning correctly. If something seems off, don’t ignore it. Waiting to fix issues can lead to accidents. Clear the area of unnecessary personnel. Proper communication is vital. Use hand signals or radios if necessary.

Be aware of your surroundings. Look out for overhead power lines or unstable ground. Staying vigilant can help prevent unexpected hazards. Practice good work habits. Keeping the workspace organized reduces confusion. Inattention or haste can lead to mistakes. Each operator should reflect on their experience to improve safety practices.

Excavation Equipment Usage Statistics

This bar chart displays the distribution of various excavation equipment used in construction projects in terms of their percentage usage. The most commonly used excavation equipment includes excavators, bulldozers, backhoes, and trenchers. Proper understanding of these figures can enhance safety and efficiency on job sites.

Maintenance and Care for Excavation Equipment

Excavation equipment plays a crucial role in construction and earthmoving projects. Proper maintenance ensures safe operations and extends the lifespan of the machines. Daily checks are often overlooked. Operators should inspect fluid levels, filters, and hoses. Neglecting these aspects can lead to costly repairs.

Cleaning the equipment after each use is vital. Dirt and debris can cause wear and tear over time. Keep areas around hydraulic lines free from clogs. Regular greasing of moving parts prevents friction-related damage. It's a small task, but many forget.

Scheduled maintenance can't be ignored. Following a set timeline for larger service needs is essential. Replace worn parts before they fail. This requires discipline but pays off in reduced downtime. Regular training on maintenance is needed too. Not every operator knows what to look for. All these efforts matter but require commitment.

Related Posts

-

How to Choose the Right Excavation Equipment for Your Project Needs

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Top 10 Equipment Construction Techniques to Boost Project Efficiency

-

Top 10 Heavy Equipment Tips Every Operator Needs to Know

-

Top Large Construction Equipment Trends to Watch in 2025

-

Top Power Heavy Equipment Types for Your Construction Needs