Top Construction Machinery and Equipment Trends to Watch in 2025

As we look ahead to 2025, the construction machinery and equipment industry is poised for significant transformation driven by technological advancements and evolving market demands. According to a recent report by the Global Construction Machinery Association, the sector is projected to grow at a compound annual growth rate (CAGR) of 5.5% over the next few years, highlighting the increasing investment in automation and sustainability.

Industry expert Dr. Alice Thompson, a leading voice in construction technology, emphasizes the importance of innovation for staying competitive, stating, "Adopting smart machinery is not just an option but a necessity for companies aiming for operational efficiency." This sentiment reflects the urgent need for organizations to integrate advanced technologies such as artificial intelligence and IoT into their operations to meet the challenges ahead.

Moreover, the ongoing shift toward eco-friendly practices demands that construction machinery and equipment evolve to reduce environmental impact. The implementation of electric and hybrid machinery is expected to surge, driven by stricter regulations and the industry's commitment to sustainability. As these trends unfold, understanding the dynamics within the construction machinery and equipment sector will be crucial for stakeholders looking to navigate the future landscape effectively.

Emerging Technologies in Construction Machinery for 2025

The construction industry is poised to experience a technological revolution by 2025, with several emerging technologies reshaping the machinery and equipment landscape. One of the most significant trends is the integration of automation in construction machinery. Automated equipment, including drones and robotic machines, is expected to improve efficiency and safety on job sites. These machines not only reduce the need for human labor in hazardous conditions but also enhance precision in tasks such as surveying and material handling, thereby minimizing errors and rework.

Another essential innovation is the rise of telematics and data analytics in construction equipment. Telematics systems enable real-time monitoring of machinery performance, fuel consumption, and maintenance needs. This data-driven approach allows contractors to optimize equipment usage, reduce downtime, and make informed decisions regarding fleet management. As predictive analytics become more sophisticated, companies will be able to foresee potential failures and schedule maintenance proactively, further enhancing operational efficiency.

Lastly, sustainability will be a crucial driver of innovation in construction machinery. With increasing regulatory pressures and a growing emphasis on environmental responsibility, the development of eco-friendly machinery is on the rise. The focus on electric-powered and hybrid machines, along with the use of sustainable materials in manufacturing, will significantly reduce carbon footprints on construction sites. These advancements highlight a shift toward eco-conscious practices in the industry, emphasizing the importance of balancing efficiency with environmental stewardship.

Advancements in Automation and Robotics in Construction Equipment

In 2025, the construction industry is poised to undergo significant transformations, particularly due to advancements in automation and robotics. As site efficiency becomes ever more crucial, construction machinery is evolving to incorporate smart technologies. Robotic equipment can perform repetitive tasks with precision, reducing human error and improving safety on-site. This shift not only enhances productivity but also addresses labor shortages by allowing fewer skilled workers to manage more complex operations.

To maximize the benefits of automated equipment, construction firms should invest in training programs for their workforce. Understanding how to operate and maintain these advanced machines is essential for ensuring smooth transitions and maximizing output. Additionally, companies could explore collaborative robots, or cobots, which work alongside human operators, enabling increased efficiency without replacing the invaluable skills of the workforce.

As the industry embraces these changes, leveraging data analytics and machine learning will become vital. Companies can collect and analyze data from their equipment and operations to predict maintenance needs and optimize performance. By focusing on these areas, construction firms can not only enhance their current operations but also prepare for the future, carving out a competitive edge in an increasingly automated landscape.

Sustainable Practices and Eco-Friendly Machinery Trends

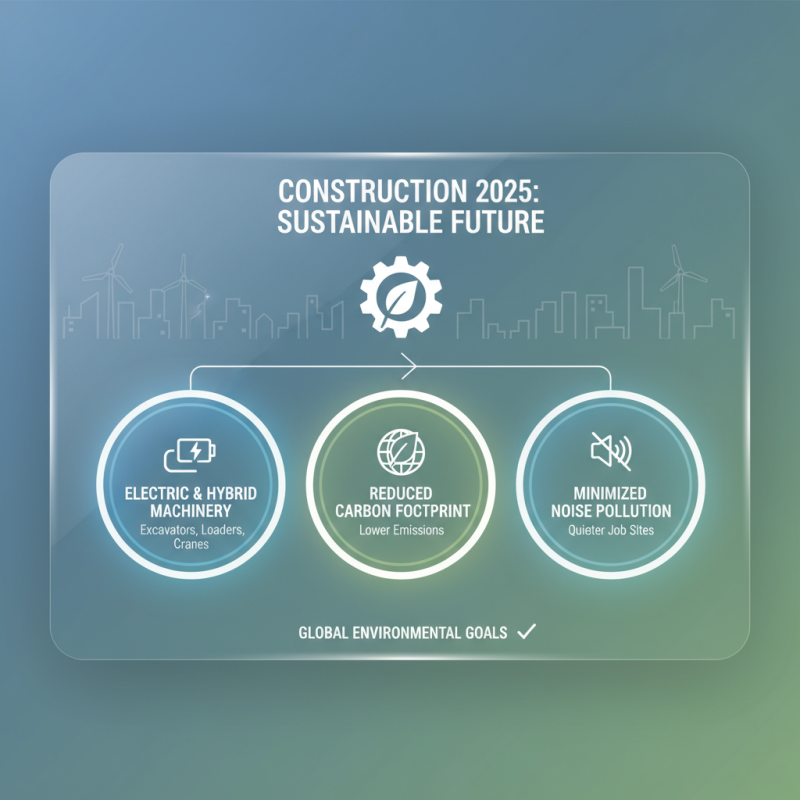

The construction industry is undergoing a significant transformation, with sustainable practices and eco-friendly machinery taking center stage as we approach 2025. One of the prominent trends is the increasing use of electric and hybrid machinery, which helps reduce carbon footprints and minimize noise pollution on job sites. Electric excavators, loaders, and cranes are not only efficient but also represent a shift towards greener operational practices. This push for electrification in heavy equipment reflects a broader commitment to sustainability, aligning with global environmental goals.

Another notable trend is the adoption of alternative fuels and energy sources. Biofuels and hydrogen-powered equipment are gaining traction as viable options to reduce reliance on fossil fuels. Furthermore, advances in battery technology are enabling machines to operate longer with less downtime for recharging, making them more attractive to construction companies focused on sustainability. Alongside machinery innovations, the industry is also prioritizing the use of recycled materials and eco-friendly construction methods, further emphasizing a holistic approach to environmentally responsible construction practices. This convergence of technology and sustainability is set to redefine the construction landscape, promoting a healthier planet for future generations.

Digitalization and Smart Equipment in the Construction Industry

The construction industry is embracing digitalization and smart equipment at an unprecedented pace, with significant implications for efficiency and productivity by 2025. A report by McKinsey & Company anticipates that digital tools could increase productivity in construction by up to 15%. By integrating technologies such as Building Information Modeling (BIM), artificial intelligence, and predictive analytics, construction firms can reduce costs and project timelines while improving quality and safety on job sites.

Moreover, the adoption of smart equipment, including autonomous machinery and Internet of Things (IoT) devices, is reshaping traditional construction practices. According to a report from Reports and Data, the global IoT in construction market is expected to grow from USD 6.5 billion in 2020 to USD 35.8 billion by 2028, reflecting a compound annual growth rate (CAGR) of 24.5%. This surge indicates a strong shift towards connected equipment that allows for real-time data sharing and enhanced decision-making, effectively transforming workflows and facilitating a more proactive approach to project management.

As these trends continue to evolve, the construction sector can look forward to smarter, more adaptive solutions that enhance collaboration and resource management. The emphasis on data-driven strategies will not only lead to more efficient construction processes but also foster sustainability as smart technologies optimize resource usage and minimize waste.

Future of Construction Safety and Worker Efficiency in 2025

As we look towards 2025, the future of construction safety and worker efficiency is poised for transformative advancements. A key trend is the integration of advanced robotics and automation, which not only enhances productivity but significantly reduces the potential for workplace accidents. By deploying drones and robotic machinery for hazardous tasks, such as high-altitude work or handling heavy materials, the risk to human workers can be minimized. Additionally, these technologies can provide real-time data and analytics that assist in making informed decisions on-site, further promoting a safer working environment.

Moreover, the increasing usage of wearable technology among construction workers is set to revolutionize safety protocols. Devices such as smart helmets and exoskeletons are designed to monitor vital signs and detect environmental hazards, alerting workers and supervisors to potential dangers before accidents occur. These innovations not just aim for physical safety but also enhance overall worker efficiency by reducing fatigue and strain, enabling workers to perform these demanding tasks more effectively. As we navigate through 2025, the convergence of technology and safety will redefine the construction landscape, creating a more secure and productive workforce.

Related Posts

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

Why Earth Moving Equipment is Essential for Modern Construction Projects

-

Best 10 Tractors and Equipment for Every Farming Need

-

Top Large Construction Equipment Trends to Watch in 2025

-

Top 10 Innovative Construction Equipment for 2024: Boost Efficiency by 30%!