How to Choose the Right Machinery Equipment for Your Industrial Needs

In the rapidly evolving landscape of industrial operations, selecting the appropriate machinery equipment stands as a critical decision that can influence productivity and efficiency. As we approach 2025, industry experts emphasize the importance of making informed choices that align with both current and future operational demands. David Johnson, a renowned expert in the machinery equipment sector, poignantly states, "The right machinery equipment not only enhances performance but also drives innovation in production processes."

Choosing suitable machinery equipment involves careful consideration of various factors, including technology trends, operational requirements, and budget constraints. With advancements in smart technology and automation reshaping the industry, businesses must evaluate how new machinery aligns with their long-term strategic goals. The importance of research and expert advice cannot be overstated in this context, particularly as emerging technologies promise to redefine what is possible in manufacturing and production.

In this guide, we will explore the "2025 Top 5" essential criteria that every organization should consider when selecting machinery equipment. By understanding these pivotal factors, manufacturers will be better equipped to navigate the complexities of their industrial needs and ensure they make sound investments that yield substantial returns.

Identifying Key Industrial Processes to Determine Machinery Requirements

Identifying the key industrial processes in your operation is crucial for determining the appropriate machinery equipment required to optimize performance. According to the 2023 Machinery Market Report by Industry Insights, over 70% of industrial failures are attributed to inadequate machinery choices that do not align with specific operational needs. Therefore, understanding the processes involved—such as material handling, assembly, and quality control—will directly influence your machinery decisions.

When evaluating your industrial processes, consider conducting a thorough analysis of the workflow to identify bottlenecks and inefficiencies. For example, a study by the International Society of Automation indicated that companies that invest in tailored machinery solutions experience a 25% increase in productivity. This highlights the importance of aligning machinery with the particular demands of each process.

Tips: Start by mapping out your entire production line to visualize the interaction between different processes. This step will allow you to pinpoint where specialized machinery can streamline operations. Additionally, consult with industry experts or leverage data from reports to stay informed on the latest technological advancements that can enhance your production capability. Investing time in understanding your processes will yield significant returns in operational efficiency and overall production capacity.

Evaluating Performance and Efficiency of Different Equipment Options

When evaluating the performance and efficiency of different machinery equipment for industrial needs, it’s crucial to establish clear benchmarks. Start by assessing the specific tasks the equipment will perform. This involves understanding the operational requirements, such as load capacities, cycle times, and the type of materials being handled. By comparing these parameters across various models, you can gauge which options provide the best performance suited to your operations.

Next, consider the energy efficiency and maintenance costs associated with each piece of equipment. High-performing machinery might offer superior output; however, if it consumes excessive energy or requires frequent repairs, its long-term viability could be compromised. Look for equipment with energy-efficient certifications and favorable maintenance records. Additionally, factor in the availability of parts and service support, as these can significantly impact the overall efficiency of operations and minimize downtime.

By systematically evaluating these aspects, you can make informed decisions that align with both performance expectations and cost-effectiveness.

Understanding Maintenance and Support to Ensure Long-Term Value

When selecting machinery equipment for industrial needs, understanding the maintenance and support aspects is crucial for ensuring long-term value. Reliable maintenance practices can significantly reduce operational costs and minimize downtime. Recent trends indicate that companies investing in predictive maintenance technologies can achieve up to 30% reduction in maintenance expenses, according to industry reports. Moreover, organizations leveraging AI-driven maintenance solutions have reported enhanced efficiency and fewer incidents of equipment failure.

**Tips:** Regularly review equipment performance and schedule routine maintenance checks. Implementing a proactive maintenance strategy not only extends the lifespan of machinery but also optimizes overall productivity.

In the context of industrial machinery, enhancing support services is equally important. Companies are increasingly adopting integrated maintenance solutions that combine real-time monitoring and predictive analytics. This approach allows businesses to respond to potential issues before they escalate, thus maximizing equipment reliability. A study shows that proactive maintenance can increase equipment availability to as high as 95%.

**Tips:** Ensure that your chosen machinery supplier offers comprehensive support services, including training and access to spare parts, to safeguard your investment and maintain operational effectiveness.

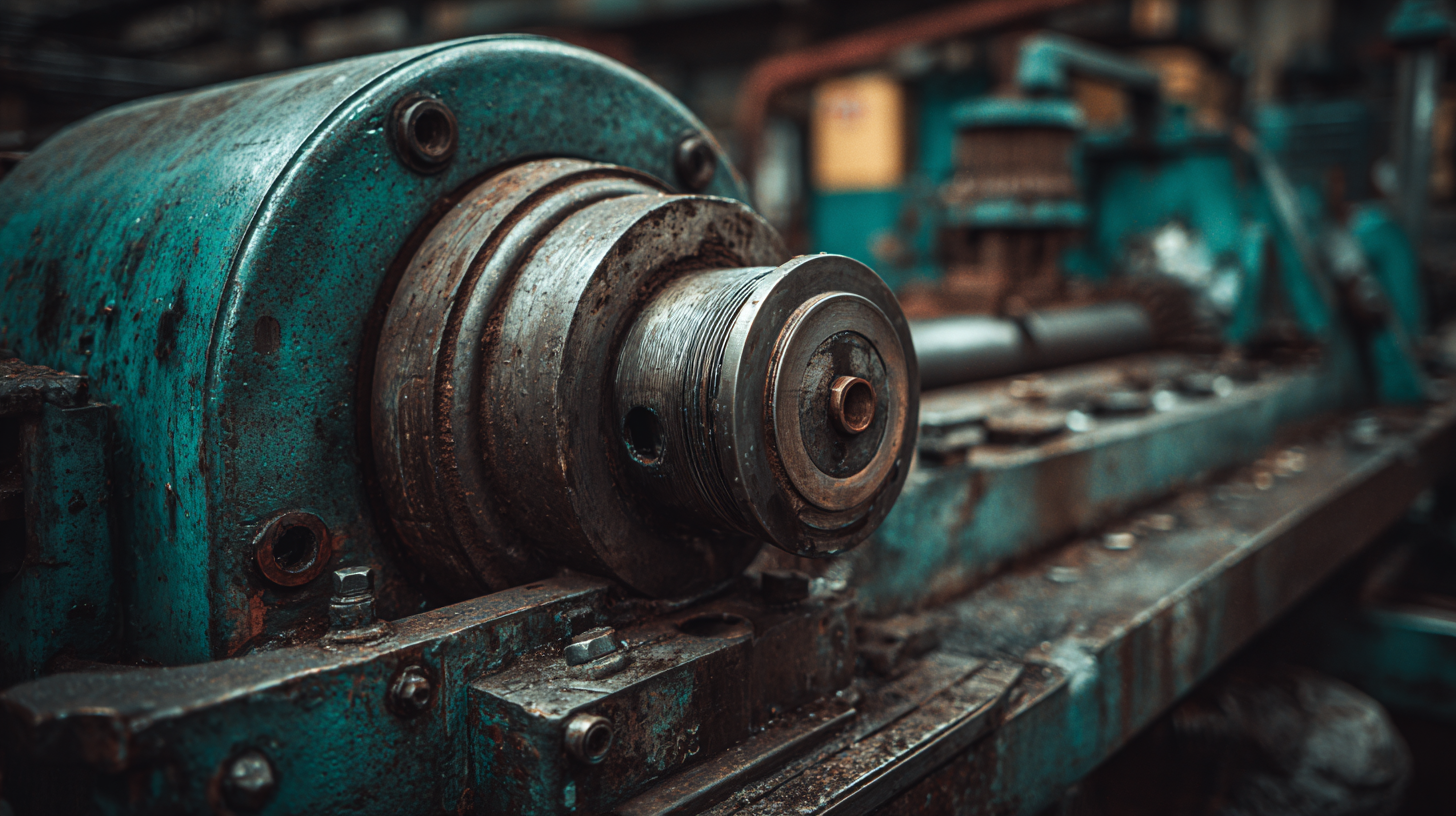

Industrial Machinery Equipment Overview

This chart illustrates the estimated annual maintenance costs for different types of industrial machinery. Understanding these costs can help you make informed decisions when selecting the right equipment for your industrial needs.

Assessing Budget Constraints and Financing Options for Machinery Purchases

When selecting machinery equipment for industrial operations, it is crucial to assess budget constraints and explore suitable financing options. Understanding the total cost of ownership, which includes not only the purchase price but also maintenance, operation, and potential downtime costs, allows businesses to establish a realistic budget. By doing so, companies can prioritize their needs and make informed decisions that align with their financial capabilities.

Financing options play a significant role in the decision-making process. Various methods such as leasing, bank loans, and financing through manufacturers can provide flexibility and meet specific cash flow requirements. Leasing machinery can lower initial expenditures and preserve capital for other operational needs, while loans can help secure the necessary funds for outright purchases. Evaluating the pros and cons of each option enables businesses to select a financing strategy that supports their operational goals while minimizing financial risk.

Researching Industry Standards and Compliance for Safety in Equipment Selection

When selecting machinery equipment for industrial applications, it is crucial to prioritize safety and compliance with industry standards. Each sector has specific regulations that dictate the minimum safety requirements for machinery. Conducting thorough research on these standards not only ensures compliance but also protects workers from potential hazards associated with equipment failure or misuse. Understanding these regulations helps in making informed decisions while shopping for machinery.

Tips: Familiarize yourself with organizations such as OSHA or ANSI, which provide essential guidelines for workplace safety and equipment standards. Additionally, consult industry-specific resources that outline necessary compliance measures relevant to your particular field.

It's also important to evaluate the track record of the equipment manufacturers regarding safety standards. Investing in equipment from reputable companies with a history of compliance can significantly reduce risks. Check certifications and endorsements from recognized bodies to ensure that the equipment has undergone rigorous safety testing and meets established industry benchmarks.

Tips: Prioritize purchasing machinery with documented safety features, such as emergency stop functions or protective guards, that further enhance worker safety and operational efficiency. Always review and stay updated on any changes to safety regulations that may affect equipment standards.