How to Choose the Right Heavy Equipment for Your Construction Project

Choosing the right heavy equipment for your construction project is crucial to ensuring efficiency, safety, and ultimately, the success of your endeavor. According to industry expert John Anderson, a seasoned construction manager with over 20 years of experience, "Selecting the appropriate heavy equipment can make the difference between a successful project and a costly delay." His insights highlight the importance of understanding not only the specifications of the machinery but also the specific needs of the project at hand.

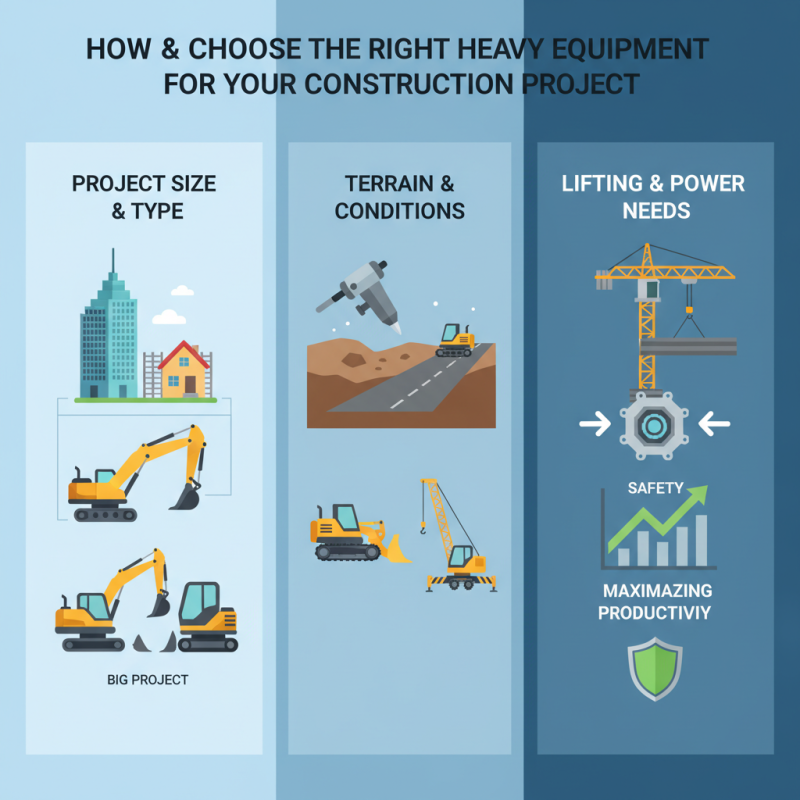

Heavy equipment encompasses a wide range of machinery, including excavators, bulldozers, and cranes, each designed for particular tasks. The decision-making process involves evaluating factors such as the project size, terrain conditions, and required lifting capacities. It is essential to conduct thorough research and consult with professionals to align equipment selection with project demands, minimizing downtime and maximizing productivity.

In conclusion, understanding the nuances of heavy equipment selection can significantly impact the economics and timeline of construction projects. By taking the time to assess needs and options, contractors can equip themselves with the tools necessary to achieve their project goals efficiently and safely.

Factors to Consider When Selecting Heavy Equipment for Construction

When selecting heavy equipment for a construction project, several key factors must be considered to ensure optimal efficiency and safety. First and foremost, it is crucial to assess the specific requirements of the project. This includes understanding the type of terrain, the scale of the construction, and the materials involved. For instance, projects requiring earthmoving may need backhoes or excavators, whereas those focused on lifting may benefit from cranes. A clear understanding of the tasks at hand will guide the selection of the appropriate machinery.

Another vital aspect is evaluating the equipment's capacity and performance capabilities. Each piece of heavy equipment has its own specifications regarding load capacities, reach, and efficiency. It's essential to choose equipment that not only fulfills the immediate needs but can also handle any unexpected challenges that arise during the project. Additionally, operators' experience and familiarity with the equipment can impact performance and safety, necessitating consideration of training and skill levels when making a decision. By aligning the equipment's capabilities with the project’s demands, teams can enhance productivity and reduce the risk of operational delays.

Types of Heavy Equipment Commonly Used in Construction Projects

When embarking on a construction project, selecting the appropriate heavy equipment is crucial to ensure efficiency and safety. Among the most commonly used types of heavy equipment are excavators, bulldozers, and cranes.

Excavators are versatile machines used for digging, lifting, and moving materials, making them essential for site preparation and foundation work. Their long arm and various attachment options enable them to perform tasks in confined spaces as well as in open areas.

Bulldozers play a vital role in ground clearing and moving large quantities of soil or debris. With their powerful blade, they are ideal for grading and leveling land, which helps create a solid and stable base for further construction activities. Another critical piece of heavy equipment is the crane, which is used to lift and place heavy materials at considerable heights. Various types of cranes, including mobile and tower cranes, are utilized depending on the specific needs of the project, offering flexibility in both urban and rural sites.

Understanding the functions and benefits of each type of equipment ensures that construction projects run smoothly and are completed on time.

Evaluating the Size and Capacity Requirements for Your Project

When embarking on a construction project, one of the first steps is to evaluate the size and capacity requirements for heavy equipment. Understanding the specific demands of your project is crucial to selecting the right machinery. Factors such as the scope of work, site conditions, and the type of materials being handled can significantly affect the size of the equipment needed. For instance, if you are dealing with large volumes of earthmoving, you'll require equipment that can handle heavier loads and have a larger bucket capacity, ensuring efficiency and productivity throughout the project.

Moreover, the terrain and access routes on the construction site play a vital role in determining the appropriate equipment size. For projects located on uneven or confined spaces, you may need compact machines that can navigate tight spots without compromising power or capacity. Assessing the ground conditions will also help in deciding whether you need wheeled or tracked equipment, as tracked vehicles are often better suited for rough terrain due to their stability and weight distribution. By thoroughly evaluating these factors, you can ensure that you select heavy equipment that not only meets the project's requirements but also enhances overall efficiency and safety during the construction process.

Understanding the Costs and Budget Implications of Heavy Equipment

When selecting heavy equipment for a construction project, understanding the costs and budget implications is crucial. The construction industry in the United States is projected to grow at an annual rate of 4.5% over the next five years, leading to increased demand for heavy machinery. A report from the Equipment Leasing and Finance Association highlights that nearly 70% of contractors face financial constraints when acquiring heavy equipment. This underscores the importance of budget planning and understanding both initial and ongoing costs associated with machinery.

The purchase price of heavy equipment is only part of the overall expenditure. Long-term costs such as maintenance, fuel, insurance, and depreciation can significantly impact your budget. According to a study by the American Rental Association, rental equipment typically incurs 20-30% less in maintenance and operational costs than owned equipment. These figures indicate that while purchasing may seem advantageous for long-term use, rental options may provide financial flexibility, especially for short-term projects or startups. Therefore, careful analysis and planning are essential to ensure the chosen equipment aligns with both immediate needs and long-term financial objectives.

Heavy Equipment Cost Analysis for Construction Projects

Safety and Compliance Regulations for Heavy Equipment in Construction

When selecting heavy equipment for your construction project, understanding safety and compliance regulations is paramount. The Occupational Safety and Health Administration (OSHA) states that approximately 20% of worker fatalities occur in the construction industry, highlighting the critical need for rigorous safety standards. Compliance with OSHA regulations not only mitigates risks but also enhances overall project efficiency. Construction managers must ensure that all equipment meets the necessary safety protocols, including proper maintenance records, preventive inspections, and operator training certifications, as mandated by industry standards.

Moreover, industry reports indicate that effective compliance with safety regulations can lead to reduced insurance costs and lower worker compensation claims. According to a 2020 study by the National Safety Council, businesses that prioritize safety can cut costs by up to 40%, providing a compelling financial incentive to adhere to regulations. Additionally, the implementation of comprehensive safety programs and regular training sessions has been shown to improve worker awareness and decrease the likelihood of accidents on site. Therefore, ensuring that heavy equipment aligns with safety regulations is not only a legal requirement but also a strategic decision that can positively impact the success of construction projects.

Related Posts

-

Top 10 Heavy Equipment Tips Every Operator Needs to Know

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Exploring the Future of Machinery and Equipment: Innovations That Will Transform Industries

-

How to Choose the Right Machinery Equipment for Your Industrial Needs

-

Top 10 Equipment Construction Techniques to Boost Project Efficiency

-

Why Earth Moving Equipment is Essential for Modern Construction Projects