How to Choose the Right Excavation Equipment for Your Project Needs

Choosing the right excavation equipment for your project is a critical step that can significantly impact the efficiency and success of your work. With a wide variety of machines available, each designed for specific tasks, understanding the nuances of excavation equipment is essential for project managers and contractors alike. Whether you're digging foundations, grading land, or carrying out utility work, selecting the appropriate equipment is key to optimizing performance, ensuring safety, and managing costs effectively.

The type of excavation equipment you choose will primarily depend on the scope and nature of your project. Factors such as soil conditions, project timeline, and required machine capabilities must all be considered. For instance, an excavator might be the best choice for heavy-duty digging tasks, while a mini-excavator may suffice for smaller jobs in confined spaces. By assessing your project needs and available equipment options, you'll be better equipped to make informed decisions that enhance productivity and reduce delays.

Ultimately, investing time in understanding and selecting the right excavation equipment can enhance the overall execution of your project. This not only leads to smoother operations but also contributes to the successful completion of tasks within budget and timeframe. As we delve deeper into the criteria for selecting excavation equipment, you'll discover the pivotal elements that will guide you in making the best choice for your specific needs.

Understanding Project Requirements for Excavation

When embarking on an excavation project, a thorough understanding of the project requirements is crucial to selecting the appropriate equipment. Project requirements can vary widely based on factors such as soil type, project scale, and intended purpose of the excavation. For instance, a project involving soft soil will necessitate different equipment compared to one dealing with rocky or compacted ground. By assessing the geological and structural characteristics of the site, project managers can better determine the size and type of machinery needed, ultimately leading to higher efficiency and productivity.

Moreover, the scale of the project significantly influences equipment choice. Smaller projects might benefit from compact machinery that offers agility and ease of maneuverability, while larger operations may require more robust machinery capable of handling extensive excavation tasks. Additionally, the depth of excavation plays a vital role; deeper projects will need specialized tools designed to reach significant depths without compromising safety. Understanding these nuances ensures that the right equipment is selected, minimizing delays, reducing costs, and enhancing overall project success.

Types of Excavation Equipment Available in the Market

When it comes to excavation projects, selecting the right equipment is crucial for efficiency and safety. There are various types of excavation equipment available in the market, each designed for specific applications. Some of the most commonly used equipment includes excavators, backhoes, bulldozers, and trenchers.

Excavators are versatile machines equipped with a boom, dipper, and bucket, making them ideal for digging deep holes and performing heavier tasks. Backhoes combine a front loader with a rear excavator, perfect for smaller jobs and tight spaces. Bulldozers are robust machines that push large quantities of material, making them essential for site preparation. Trenchers are specialized tools for digging trenches, often used in utility installation projects.

**Tips for choosing the right excavation equipment:**

1. Assess the scope and scale of your project. For larger sites, heavy-duty machinery like excavators or bulldozers may be required, while smaller jobs might only need a backhoe.

2. Consider the terrain and soil type. Some machines perform better on rocky or uneven ground, so ensure you select equipment that can handle your specific environment.

3. Evaluate the equipment's capabilities, such as digging depth and load capacity. This ensures that you can meet the demands of your project effectively and without delays.

Factors to Consider When Selecting Excavation Equipment

When selecting excavation equipment for a project, several key factors should be taken into account to ensure efficiency and effectiveness. First, the type of work involved is paramount; different tasks, such as digging, grading, or trenching, require specialized machinery. Understanding the specific requirements of the project can help in determining whether a mini-excavator, backhoe, or larger excavator is necessary. Additionally, assess the ground conditions and terrain. Soft soil may benefit from lighter equipment, while rocky or compacted environments might necessitate more robust machinery.

Another crucial factor to consider is the project's scale and timeline. For large projects with tight deadlines, high-capacity equipment that can move quickly and handle significant workloads may be required. Conversely, for smaller jobs, compact and versatile machines might suffice, as they can easily navigate restricted spaces. Additionally, budget considerations play a vital role; understanding the cost of rental versus purchasing equipment can impact decision-making. Overall, taking the time to analyze these factors thoroughly will lead to selecting the most appropriate excavation equipment for your specific project needs.

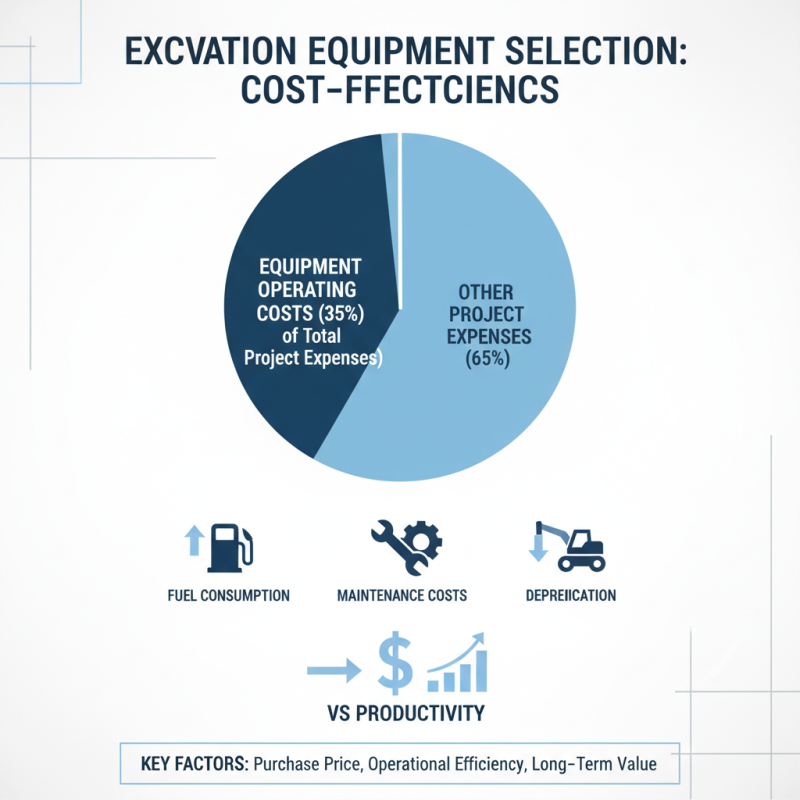

Evaluating Budget and Cost-Effectiveness of Equipment

When selecting excavation equipment for a project, understanding the budget and cost-effectiveness is crucial. According to a report by the Associated Equipment Distributors, equipment operating costs can typically account for up to 35% of total project expenses. This highlights the importance of evaluating not just the purchasing price of the equipment, but also its long-term operational efficiency. Factors such as fuel consumption, maintenance costs, and depreciation should be assessed in relation to the equipment's productivity.

In addition, a study from the Construction Industry Institute suggests that investing in high-efficiency equipment can yield significant savings over time. For instance, using excavators designed with fuel-efficient technology can reduce fuel costs by as much as 20%. Moreover, modern equipment often incorporates advanced technology that minimizes downtime through better diagnostics and predictive maintenance, further enhancing cost-effectiveness. Therefore, when evaluating excavation machinery, one should not only consider upfront costs but also long-term financial implications, ensuring that the equipment selected aligns effectively with both current project needs and future operational goals.

Maintenance and Support for Excavation Equipment Use

Maintaining excavation equipment is crucial for ensuring optimal performance and longevity. Regular maintenance routines should include checks on hydraulic systems, engine components, and structural integrity. Operators should be trained to identify signs of wear and tear, such as leaks or overheating. Implementing a systematic maintenance schedule not only enhances safety but also minimizes unforeseen breakdowns that could delay project timelines.

In addition to routine maintenance, having reliable support is essential for excavation equipment. Establishing a relationship with knowledgeable service providers can provide access to rapid repairs and technical assistance when challenges arise. Keeping an inventory of essential spare parts can also reduce downtime, allowing teams to respond swiftly to equipment failures. By prioritizing maintenance and support, project managers can ensure that their excavation equipment remains in top condition, thus supporting efficient project execution.

Excavation Equipment Utilization by Type

Related Posts

-

Top 10 Essential Construction Equipment Every Builder Should Own

-

How to Safely Move Large Equipment in 2025 for Maximum Efficiency and Minimal Risk

-

How to Choose the Right Machinery Equipment for Your Industrial Needs

-

How to Choose the Right Machinery Moving Equipment for Your Needs

-

Why Earth Moving Equipment is Essential for Modern Construction Projects

-

What is Power Equipment and How to Choose the Right Type for Your Needs