How to Choose the Best Electric Construction Equipment for Your Projects

In the rapidly evolving landscape of construction, the importance of selecting the right electric construction equipment has never been more critical. As James Turner, a leading expert in the field of construction technology, aptly stated, “The future of construction lies in sustainable practices, and electric construction equipment is at the forefront of this transformation.” With increasing pressure to reduce carbon footprints and enhance operational efficiency, construction professionals are turning to electric solutions that not only meet regulatory demands but also pave the way for innovation.

Choosing the best electric construction equipment for your projects involves a comprehensive assessment of various factors, including power requirements, battery life, and the specific tasks at hand. This decision-making process is crucial, as selecting the appropriate tools can significantly impact productivity and project outcomes. Moreover, the transition to electric equipment represents a commitment to sustainability, aligning with the growing trend towards eco-friendly construction practices that prioritize the environment while maintaining high standards of performance.

As we delve into the critical aspects of selecting electric construction equipment, we aim to provide insights that cater to both seasoned professionals and newcomers in the industry. By understanding the available options and their capabilities, you can optimize your operations and contribute to a greener future in construction.

Factors to Consider When Selecting Electric Construction Equipment

When selecting electric construction equipment for your projects, several critical factors should be carefully considered to ensure optimal performance and efficiency. Firstly, the power requirements of the equipment must align with the demands of your projects. According to a report by the International Energy Agency, between 2010 and 2020, the growth in electric construction equipment was driven largely by increased demand for energy efficiency and reduced emissions. Understanding the energy consumption ratings and output capabilities will help you choose equipment that meets project needs without exceeding energy budgets.

Another key consideration is the equipment's compatibility with existing job site conditions. This involves evaluating the size and weight of the equipment, as well as its maneuverability in constrained work environments. A study by the National Institute of Standards and Technology found that improper equipment selection can lead to increased time and costs on construction projects. Additionally, consider the availability of charging infrastructure and battery life, as these factors directly impact the operational efficiency. The transition to electric equipment necessitates a thorough analysis of charging options to avoid downtime during projects. In 2022, it was reported that nearly 40% of construction firms faced challenges related to insufficient charging facilities on-site, highlighting the importance of planning for energy logistics in your equipment selection process.

Comparison of Electric Construction Equipment by Power Output

Types of Electric Construction Equipment Available on the Market

When selecting electric construction equipment for your projects, it's essential to explore the various types available on the market. Electric tools and machinery can significantly enhance efficiency and reduce emissions on job sites. Common types of electric construction equipment include electric drills, concrete mixers, saws, and compactors. Each piece possesses its unique features catering to different construction tasks, from small-scale home renovations to large construction projects.

Tips: When choosing electric equipment, consider the power source and battery life for portable tools, as these factors directly impact efficiency. It's also vital to assess the weight and ergonomics of the machinery to ensure ease of use and reduce fatigue during extended work periods.

Moreover, ensure compatibility with your current tools and consider the maintenance requirements of the equipment. Regular maintenance can prolong the life of electric tools and enhance performance. By evaluating the specific requirements of your project and the available electric equipment, you can make informed decisions that lead to improved productivity and sustainability in your construction efforts.

Understanding Power Requirements and Efficiency Ratings

When selecting electric construction equipment for your projects, understanding power requirements is crucial to ensuring optimal performance and efficiency. Different tools and machinery have varying power demands that can affect their effectiveness in specific tasks. It is essential to evaluate the voltage and amperage ratings of the equipment, as these specifications determine how well the machinery operates under different conditions.

For example, more powerful equipment may be necessary for heavy-duty tasks, while lighter tasks can be efficiently handled by tools with lower power ratings.

In conjunction with power requirements, efficiency ratings are a key factor to consider. These ratings indicate how effectively a piece of equipment converts electrical energy into productive work, which can lead to reduced operational costs and lower environmental impact. Equipment that boasts high efficiency ratings will not only save energy but also reduce downtime, as they are often designed for better performance and reliability. When comparing options, look for energy-efficient models that meet the demands of your projects while providing long-term savings and sustainable performance.

Evaluating Durability and Maintenance Needs of Equipment

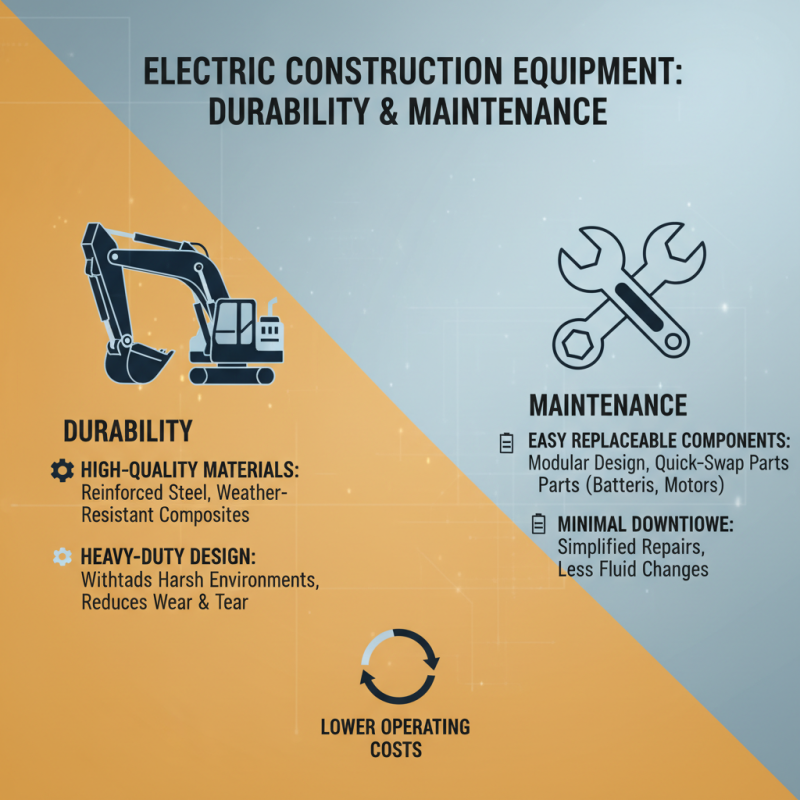

When selecting electric construction equipment for your projects, evaluating the durability and maintenance needs of the machinery is crucial. Durability refers to the equipment’s ability to withstand the wear and tear of regular use, particularly in demanding environments. Look for equipment constructed from high-quality materials that can endure heavy workloads and adverse weather conditions. The design should also consider components that are easily replaceable, minimizing downtime when repairs are needed.

Maintenance needs are another critical aspect to consider. Equipment that requires frequent maintenance can lead to interruptions in project timelines and increased costs. Investigate the maintenance requirements of different models, focusing on factors such as the frequency of servicing, availability of spare parts, and ease of access to components for repairs. Additionally, equipment with user-friendly maintenance features can simplify routine checks and prolong the lifespan of the machinery, making it a better investment for the long term. Choosing equipment that balances durability with manageable maintenance needs will enhance efficiency and reliability throughout the construction process.

Budgeting and Cost Analysis for Electric Construction Tools

When selecting electric construction equipment, budgeting and cost analysis are crucial steps that can substantially impact the overall success of your projects. First, it is essential to evaluate both the initial acquisition costs and the long-term operational expenses. This includes not only the purchase price of the equipment but also factors such as maintenance, energy consumption, and the lifespan of the tools. A thorough understanding of these elements allows you to assess the total cost of ownership (TCO), helping you make informed decisions that align with your financial resources.

Moreover, consider the types of projects you will undertake and estimate the frequency of use for the equipment. This will help in determining whether to purchase, lease, or rent the equipment. Leasing or renting may offer more flexibility and reduce immediate financial outlays for short-term projects. Additionally, explore potential savings through energy-efficient tools that might have a higher upfront cost but yield lower operational expenses and enhanced productivity over time. By incorporating a comprehensive cost analysis into your budgeting process, you can ensure that you select the electric construction tools that best fit your project needs while maintaining financial viability.

How to Choose the Best Electric Construction Equipment for Your Projects - Budgeting and Cost Analysis for Electric Construction Tools

| Equipment Type | Average Cost ($) | Power Rating (kW) | Battery Life (hrs) | Weight (lbs) |

|---|---|---|---|---|

| Electric Concrete Mixer | 750 | 2.2 | 3 | 120 |

| Electric Compressor | 850 | 3.0 | 4 | 130 |

| Electric Saw | 300 | 1.5 | 2.5 | 75 |

| Electric Hammer Drill | 450 | 2.0 | 3.5 | 80 |

| Electric Pressure Washer | 400 | 1.8 | 2 | 70 |

Related Posts

-

How to Learn to Operate Heavy Equipment for a Successful Career

-

How to Choose the Right Machinery Equipment for Your Industrial Needs

-

Why Earth Moving Equipment is Essential for Modern Construction Projects

-

Understanding the Impact of Heavy Earth Moving Equipment on Modern Construction Projects

-

Top Power Heavy Equipment Types for Your Construction Needs

-

Top 10 Equipment Construction Techniques to Boost Project Efficiency